Why Cryogenic Pumps Matter in LNG and Industrial Gas Operations

Cryogenic pumps are essential for transferring liquefied gases — such as LNG, liquid nitrogen, oxygen, argon, and CO₂ — from storage tanks to pipelines, tankers, or process systems. Unlike standard pumps, cryogenic pumps are engineered to operate reliably at ultra-low temperatures (down to -196°C / -321°F), ensuring high flow rates, minimal boil-off, and safe pressurization. They play a vital role in energy, aerospace, medical, and industrial manufacturing sectors where liquid gases are integral to production and operations.

Key Types of Cryogenic Pumps

Different industrial processes demand different cryogenic pump designs. Choosing the right one depends on flow capacity, operating pressure, and duty cycle requirements.

| Pump Type | Operation Principle | Best For |

|---|---|---|

| Submerged Pump | Motor and impeller fully submerged in the cryogenic liquid, minimizing heat ingress. | Continuous LNG transfer and fueling stations |

| Reciprocating Pump | Piston-driven, positive displacement design for high pressure output. | High-pressure industrial gas cylinder filling |

| Centrifugal Pump | Rotating impeller delivers large volume flows with low pulsation. | LNG terminal ship loading/unloading |

| Regenerative Turbine Pump | Compact high-head pump with low flow rates. | Small-scale cryogenic systems |

| Screw Pump | Twin-screw design for smooth and continuous flow. | Industrial processes needing stable flow |

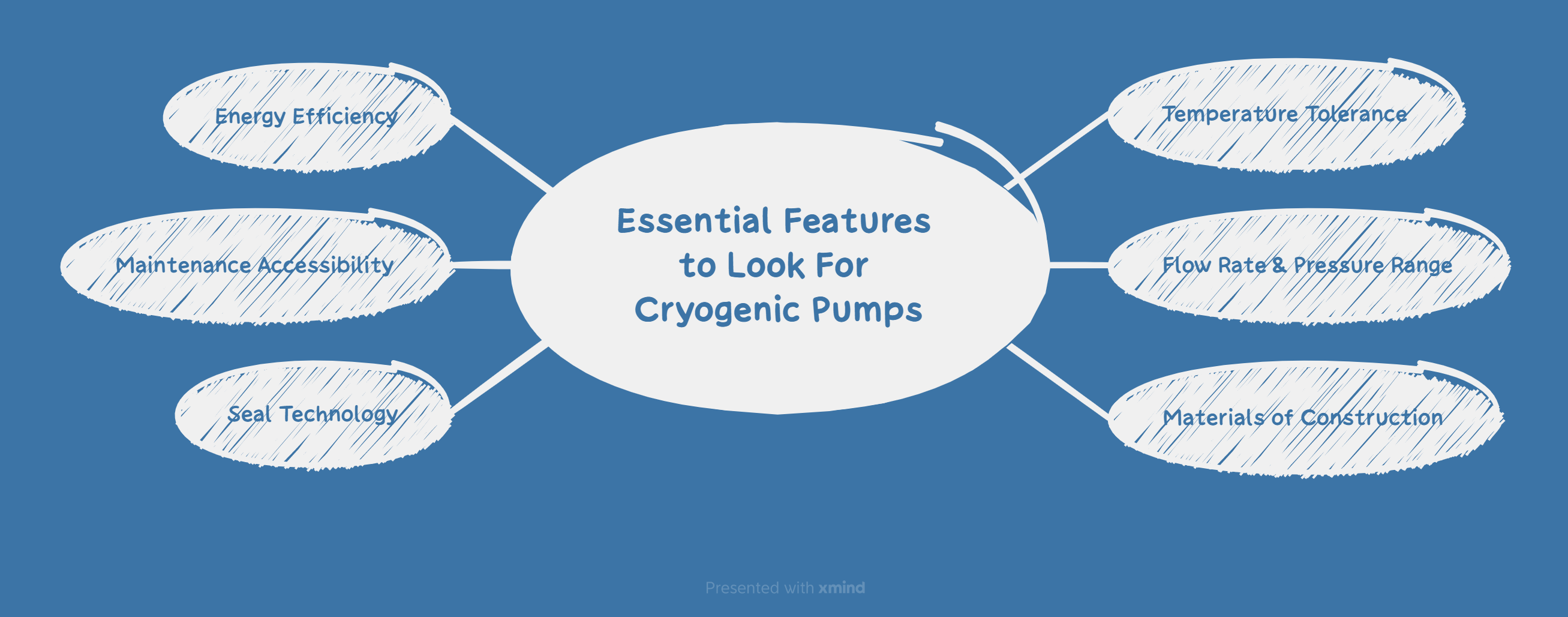

Essential Features to Look For Cryogenic Pumps

For maximum reliability and efficiency, the best cryogenic pumps should meet the following criteria:

- Temperature Tolerance – Ability to handle the cryogenic liquid's boiling point without material embrittlement.

- Flow Rate & Pressure Range – Matching pump performance to process demand.

- Materials of Construction – Austenitic stainless steels to resist low-temperature brittleness.

- Seal Technology – Mechanical seals designed for cryogenic operation to minimize leakage.

- Maintenance Accessibility – Modular pump designs for quick inspection and part replacement.

- Energy Efficiency – Optimized hydraulic design to reduce operational costs.

Pricing Overview for 2025

Prices for cryogenic pumps vary based on type, flow capacity, pressure rating, materials, and certification standards.

| Pump Type | Price Range (USD) | Typical Application |

|---|---|---|

| Submerged LNG Pump | $8,000 – $25,000 | LNG fueling stations |

| Reciprocating High-Pressure Pump | $10,000 – $30,000 | Industrial gas cylinder filling |

| Large Centrifugal Pump | $20,000 – $60,000 | LNG ship loading terminals |

| Portable Cryogenic Pump | $5,000 – $12,000 | Mobile cryogenic liquid transfer |

CryoTech offers tailored pricing based on customer-specific requirements and compliance needs, ensuring cost-effectiveness without compromising safety or performance.

Matching a Pump to Your Application

Selecting the correct cryogenic pump requires a clear understanding of your operational parameters:

- The type of cryogenic liquid to be pumped (LNG, LOX, LIN, LAr, CO₂).

- Required flow rate and discharge pressure.

- Continuous or intermittent operation requirements.

- Space, power supply, and environmental constraints.

- Compliance with relevant regional and international standards.

CryoTech’s engineering team offers consultations to ensure pump specifications align perfectly with operational needs.

Maintenance and Operational Best Practices

Proper maintenance extends pump life and ensures consistent performance:

- Follow warm-up and cooldown procedures to prevent thermal shock.

- Lubricate seals and bearings as per manufacturer recommendations.

- Inspect suction lines to prevent vapor lock and cavitation.

- Perform regular non-destructive testing (NDT) on pressure components.

With CryoTech’s service support, industrial users benefit from predictive maintenance programs that minimize unplanned downtime.

Where to Source High-Performance Cryogenic Pumps

While there are numerous suppliers, only a few deliver custom-engineered solutions with full technical support. CryoTech distinguishes itself by offering in-house design, manufacturing, ISO/CE/ASME certification, and worldwide delivery, ensuring performance, safety, and regulatory compliance.

Conclusion

The best cryogenic pump is defined by its ability to deliver reliable, efficient, and safe performance under extreme low-temperature conditions. CryoTech’s range of pumps combines precision engineering with application-specific customization, making it the trusted choice for LNG, industrial gas, and other cryogenic liquid handling needs.

FAQ: Cryogenic Pumps

What liquids can cryogenic pumps handle?

They are designed to transfer liquefied gases such as LNG, liquid nitrogen, oxygen, argon, and CO₂ at extremely low temperatures.

How often do cryogenic pumps require maintenance?

Routine inspections are recommended monthly, with full servicing typically required annually, depending on usage and operating conditions.

What is the difference between a submerged and a reciprocating cryogenic pump?

Submerged pumps are ideal for continuous, high-volume transfer, while reciprocating pumps are better for high-pressure applications like gas cylinder filling.

Can cryogenic pumps be customized?

Yes. CryoTech provides custom designs to match specific flow rates, pressures, and compliance standards for each client's application.

What factors affect the price of a cryogenic pump?

Key factors include pump type, flow capacity, pressure rating, materials, and certifications. Additional features such as automated controls may also influence cost.

.png)

.png)