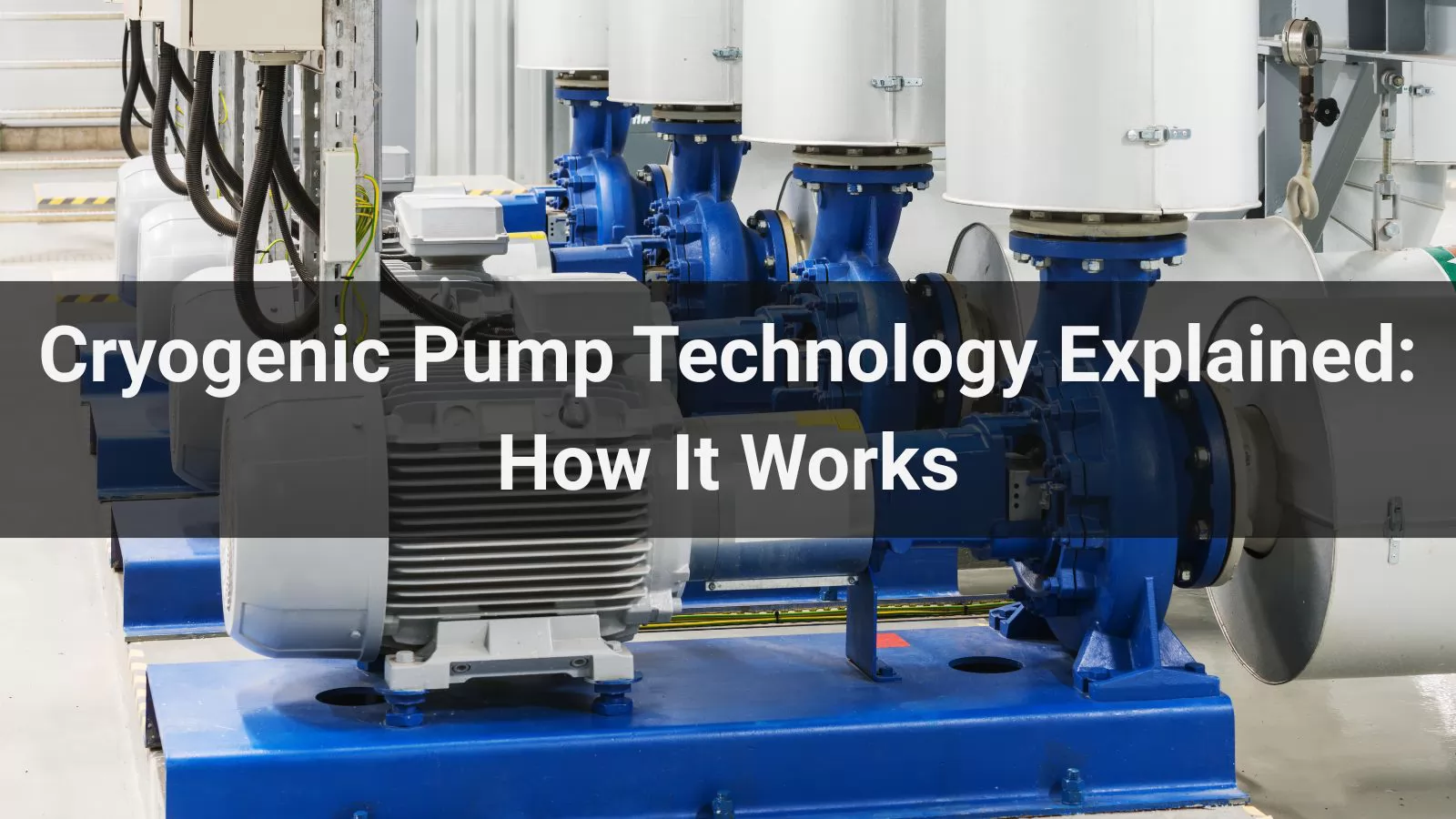

Cryogenic pumps are the backbone of many industries that rely on extremely low-temperature fluids, from liquefied natural gas (LNG) transport to medical oxygen supply. This article dives deep into the principles, operation, and applications of cryogenic pump technology, offering a clear, professional understanding for engineers, operators, and decision-makers.

Understanding the Science Behind Cryogenic Pumps

A cryogenic pump is specifically designed to handle liquids at temperatures below -150°C (-238°F). These temperatures are far below what conventional pumps can manage, requiring specialized materials, insulation, and sealing systems to prevent heat ingress and vaporization.

- Working Mediums: LNG, liquid oxygen (LOX), liquid nitrogen (LIN), liquid hydrogen (LH2), and liquid argon (LAR).

- Temperature Range: Typically between -150°C and -273°C.

- Design Focus: Minimized heat leak, robust bearings, and compatibility with low-viscosity fluids.

The Core Working Principle

At the heart of cryogenic pump technology is the need to transfer cryogenic liquids without allowing them to vaporize. The pump achieves this by maintaining a sealed, insulated environment and using materials capable of withstanding thermal stress.

- Fluid Intake: Cryogenic liquid enters the pump chamber from a storage tank or transfer line.

- Pressurization: An impeller, reciprocating piston, or screw mechanism pressurizes the liquid to the required discharge pressure.

- Heat Management: Insulation layers and cold-end sealing prevent thermal gain that could cause flashing.

- Discharge: The liquid exits under pressure, ready for transport or processing.

Different Types of Cryogenic Pumps

The choice of pump type depends on flow rate, pressure requirements, and operational conditions:

| Type |

|---|

| Operation Principle | Common Applications | |

|---|---|---|

| Centrifugal Cryogenic Pump | Uses high-speed impellers for continuous, smooth flow. | LNG ship loading, continuous transfer lines. |

| Reciprocating Piston Pump | Delivers high-pressure output through back-and-forth motion. | Cryogenic cylinder filling, high-pressure gas supply. |

| Screw Cryogenic Pump | Rotating screws push liquid through at stable pressure. | Industrial gas plants, refrigeration systems. |

Innovations in Cryogenic Pump Technology

Modern cryogenic pumps integrate advanced sealing technology, magnetic coupling systems, and composite insulation materials to improve efficiency and reduce downtime. Some designs now feature IoT-enabled monitoring for real-time performance tracking.

Applications Across Industries

Cryogenic pumps are vital in:

- Energy Sector: LNG production, storage, and ship-to-shore transfer.

- Healthcare: Liquid oxygen supply for hospitals and laboratories.

- Manufacturing: Metal processing using liquid nitrogen cooling.

- Research: Particle accelerators and superconducting magnet systems.

Operational Best Practices

To ensure optimal performance and longevity of cryogenic pumps:

- Pre-cool the pump before operation to prevent thermal shock.

- Maintain correct insulation thickness and inspect regularly.

- Monitor vibration levels and bearing wear.

- Follow manufacturer-recommended maintenance intervals.

Choosing the Right Cryogenic Pump

Selection should be based on required flow rate, discharge pressure, fluid type, and intended duty cycle. Partnering with an experienced manufacturer ensures the pump meets your exact operational needs.

Conclusion

Cryogenic pump technology is a critical enabler in industries that handle ultra-low-temperature liquids. Understanding how these pumps work, the available types, and their operational requirements can help you make informed decisions that improve efficiency, safety, and cost-effectiveness.

.png)

.png)

![Top 10 LNG Tank Manufacturers Worldwide[2026 Updated]](/uploads/202506/CryoTech-banner-1-_1750490922_WNo_800d450.jpg)

![Top 10 Cryogenic Companies in USA[2026 Updated]](/uploads/202508/bannerlist_1756363009_WNo_800d450.jpg)