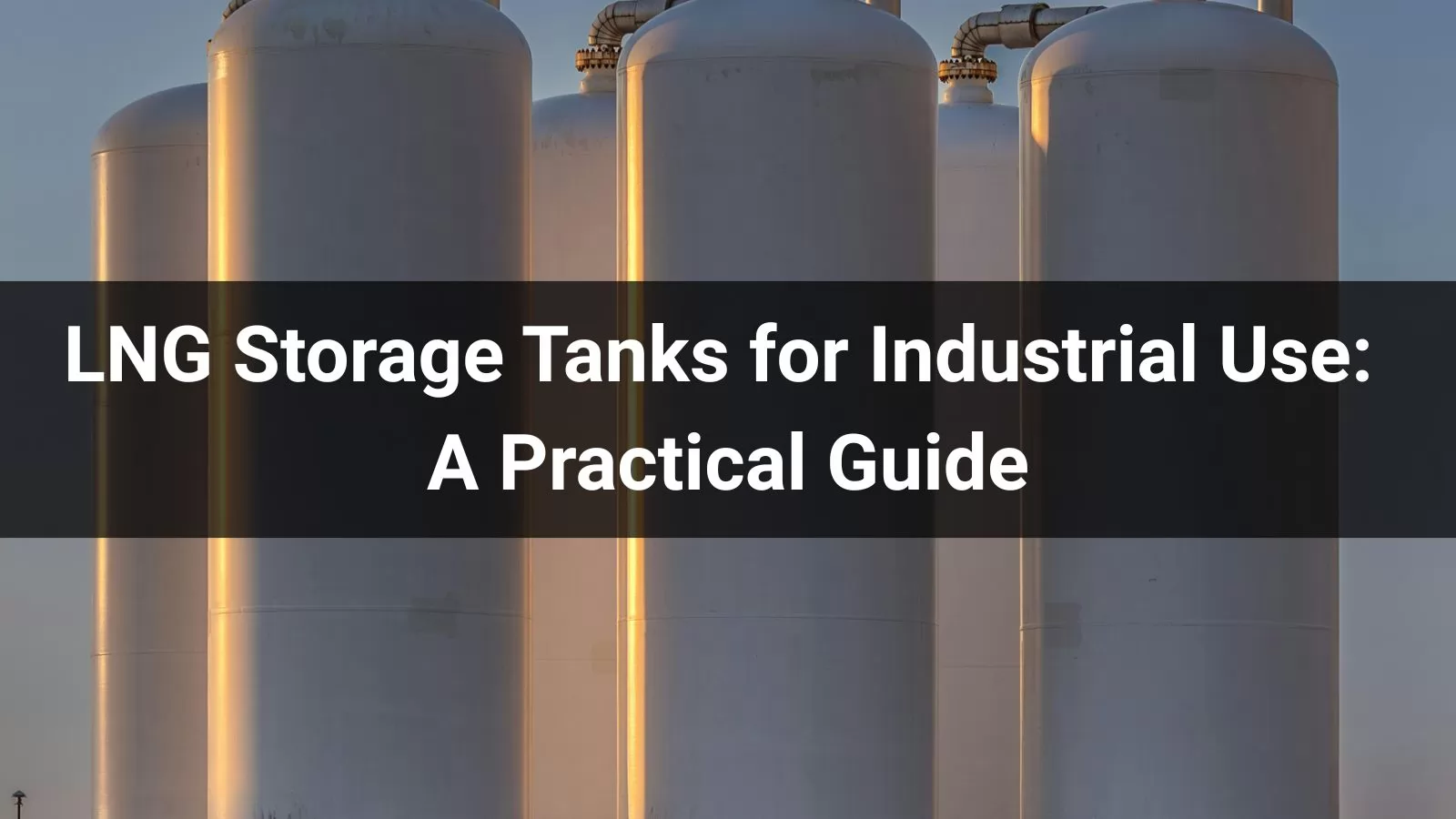

1. LNG in the Industrial Landscape

Liquefied Natural Gas (LNG) has become a cornerstone fuel in many industrial sectors — from power generation to steel manufacturing, chemical processing, and off-grid energy supply. Its high energy density and cleaner combustion profile make it an attractive alternative to heavy fuel oil or coal. However, LNG must be stored at approximately -162°C (-260°F), requiring specialized cryogenic storage tanks engineered for long-term safety and efficiency.

2. Types of LNG Storage Tanks Used in Industry

| Tank Type | Description | Best For |

|---|---|---|

| Above-Ground Vertical Tank | Double-walled, vacuum-insulated cylindrical tanks with high capacity. | Industrial sites with stable LNG demand |

| Horizontal Tank | Compact design, often skid-mounted for ease of installation. | Facilities with limited height clearance |

| Bullet Tank | Horizontal elongated design for high-pressure LNG storage. | Transport and fast-fill stations |

| Full Containment Tank | Inner steel tank and outer concrete tank for maximum safety. | Large-scale LNG terminals and plants |

| Transportable ISO Tank | Containerized LNG tank for road, rail, or sea transport. | Remote energy supply and mobile fueling |

3. Capacity Planning: How to Determine the Right Tank Size

Choosing the correct LNG storage capacity is essential for operational continuity and cost efficiency. Consider:

- Daily Consumption Rate – Average LNG usage in cubic meters per day.

- Refill Cycle – Interval between LNG deliveries.

- Boil-Off Gas (BOG) Rate – LNG loss due to heat ingress.

- Peak Demand – Short-term consumption spikes.

Tank Capacity (m³) = (Daily Consumption × Days Between Refills) × (1 + Safety Margin)

CryoTech engineers can simulate real operational loads and recommend the most cost-effective tank size, reducing both fuel wastage and logistics costs.

4. Insulation and Thermal Efficiency

For LNG tanks, insulation is the single most important factor in minimizing heat ingress and BOG losses. CryoTech uses:

- Vacuum-Perlite – A high-performance bulk insulation with low thermal conductivity.

- Multi-Layer Insulation (MLI) – Multiple reflective foil layers to block radiant heat.

- Hybrid Systems – Combining perlite and MLI for optimal performance in harsh climates.

Thermal modeling is conducted for each design to ensure LNG remains in liquid form for extended storage durations.

5. Safety and Compliance Requirements

LNG storage tanks for industrial use must comply with global and regional standards, including:

- ASME Section VIII – Pressure vessel construction.

- EN 1473 – LNG onshore storage guidelines.

- NFPA 59A – US LNG safety requirements.

- ISO 21009-2 – Operational standards for cryogenic vessels.

Safety measures integrated into CryoTech tanks include double relief valve systems, continuous gas leak detection, emergency vent stacks, and reinforced outer shells for impact protection.

6. Installation Considerations for Industrial Sites

Proper installation of LNG tanks affects both performance and safety:

- Foundation Engineering – Design to support full load and prevent frost heave in cold climates.

- Optimized Piping Layout – Shorter LNG transfer lines reduce thermal losses.

- Ventilation Planning – Gas dispersion modeling to prevent hazardous accumulation.

- Spill Containment – Secondary containment structures to manage leaks.

- Access Roads – Facilitating tanker truck maneuverability and refueling operations.

CryoTech provides on-site project management, from civil works to final commissioning, ensuring compliance and operational readiness.

7. Maintenance and Lifecycle Management

Routine maintenance keeps LNG tanks operating safely and extends their lifespan:

- Daily: Check pressure, temperature, and liquid levels.

- Monthly: Inspect valves, gauges, and insulation integrity.

- Quarterly: Test safety valves and alarm systems.

- Annually: Perform non-destructive testing (NDT) on structural welds and shell plates.

CryoTech offers predictive maintenance services using IoT sensors to monitor tank health in real time, minimizing downtime and repair costs.

8. Integrating LNG Tanks into Industrial Energy Systems

LNG tanks can be integrated into a variety of energy configurations:

- Direct Fuel Supply – For industrial boilers, furnaces, and turbines.

- Regasification and Pipeline Injection – Supplying natural gas to process lines.

- Hybrid Energy Systems – Combining LNG with solar, wind, or battery storage for off-grid operations.

CryoTech provides end-to-end engineering for LNG energy integration, including control systems, flow metering, and automated BOG recovery to maximize energy utilization.

9. Cost Factors and ROI Analysis

The investment in LNG storage tanks depends on capacity, material choice, insulation type, and regulatory features. However, LNG often offers significant cost advantages over diesel or LPG for high-volume users.

Benefits of LNG storage include:

- Fuel cost savings up to 25–40% compared to diesel.

- Lower greenhouse gas emissions, aiding compliance with environmental regulations.

- Stabilized energy supply in remote or off-grid locations.

With proper sizing and integration, typical ROI periods for industrial LNG storage systems range from 2 to 5 years.

10. Conclusion: LNG Storage as a Strategic Industrial Asset

LNG storage tanks are not merely containers — they are critical infrastructure for reliable, efficient, and sustainable energy supply in industrial environments. With decades of engineering experience, CryoTech delivers fully compliant, high-performance LNG tanks tailored to client needs, ensuring safety, operational efficiency, and long-term value.

.png)

.png)