The cryogenic trailer manufacturing industry represents a critical segment of specialized transportation equipment, designed to safely transport extremely low-temperature liquids such as liquid nitrogen, liquid oxygen, liquid argon, and liquefied natural gas (LNG). These sophisticated vehicles require advanced engineering, superior insulation technologies, and stringent safety standards to maintain temperatures as low as -196°C (-320°F).

The global cryogenic trailer market has experienced significant growth, driven by increasing demand from healthcare, food processing, energy, and industrial gas sectors. As industries worldwide adopt more sustainable and efficient transportation methods for cryogenic materials, the role of specialized manufacturers becomes increasingly vital.

This comprehensive guide examines the world's leading cryogenic trailer manufacturers, analyzing their capabilities, technological innovations, and market positions to help industry professionals make informed decisions when selecting equipment suppliers.

CryoTech stands as a distinguished leader in the cryogenic trailer manufacturing industry, combining decades of engineering expertise with cutting-edge innovation to deliver superior transportation solutions for the most demanding applications.

Our commitment to excellence extends beyond manufacturing to encompass comprehensive customer support, rigorous quality assurance, and continuous technological advancement. CryoTech's trailers are engineered to exceed industry standards while providing exceptional reliability and operational efficiency.

1. Advanced Insulation Technology: Proprietary vacuum-insulated systems that minimize heat transfer and maximize payload efficiency

2. Customization Capabilities: Tailored solutions designed to meet specific customer requirements and operational needs

3. Global Service Network: Comprehensive support infrastructure ensuring rapid response times and minimal downtime

4. Regulatory Compliance: Full adherence to international safety standards including DOT, ADR, and ASME certifications

5. Innovative Design: Lightweight construction materials that increase payload capacity while maintaining structural integrity

CryoTech's portfolio includes specialized trailers for liquid nitrogen, oxygen, argon, carbon dioxide, and LNG applications, each engineered with precision to ensure optimal performance across diverse operating conditions. Our manufacturing facilities utilize state-of-the-art equipment and quality control processes, resulting in products that consistently exceed customer expectations.

The following manufacturers represent the industry's most influential companies, selected based on market presence, technological capabilities, manufacturing capacity, and global reach. Each company brings unique strengths to the cryogenic transportation sector.

| Rank | Manufacturer | Headquarters | Primary Markets | Specialization |

|---|---|---|---|---|

| 1 | Chart Industries | USA | Global | Industrial Gases, LNG |

| 2 | CIMC Enric | China | Asia-Pacific | Multi-purpose Cryogenic |

| 3 | Heil Trailers | USA | North America | Liquid Nitrogen/Oxygen |

| 4 | Polar Tank Trailer | USA | North America | Industrial Applications |

| 5 | Cryolor | France | Europe | Air Gas Transport |

| 6 | Taylor-Wharton | USA | Global | LNG, Industrial Gases |

| 7 | Wessington Cryogenics | UK | Europe | Custom Solutions |

| 8 | INOXCVA | India | Asia, Middle East | Hydrogen, Multi-gas |

| 9 | FIBA Technologies | USA | North America | Tube Trailers |

| 10 | Cryo-Tech | China | Asia-Pacific | LNG Trailers |

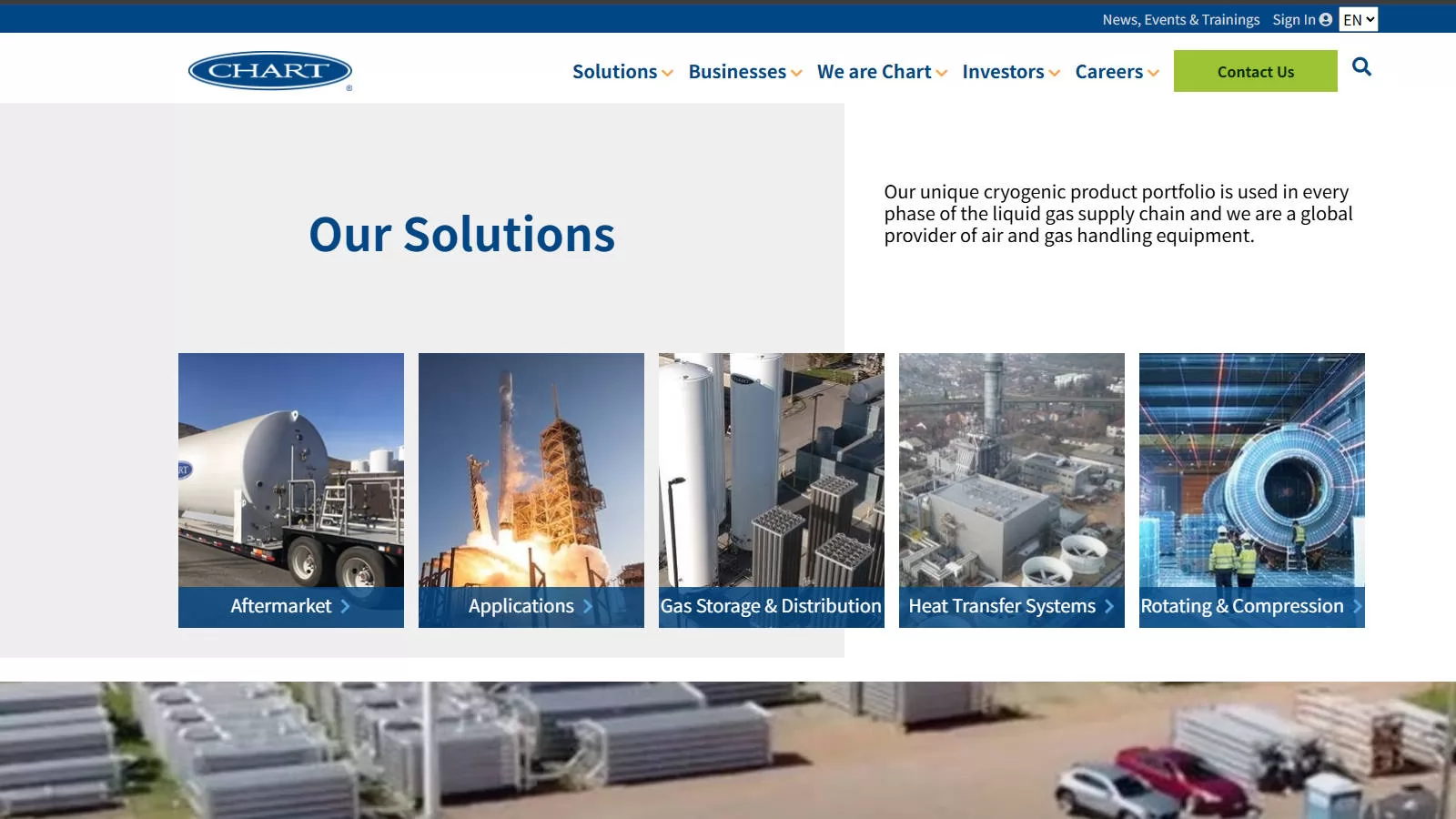

Headquarters: Georgia, USA | Founded: 1992 | Global Presence: Manufacturing facilities in North America, Europe, and Asia

Company Overview: Chart Industries is a leading global manufacturer of engineered equipment servicing multiple applications in the Energy and Industrial Gas markets. The company has established itself as the world's largest independent manufacturer of cryogenic equipment with a comprehensive portfolio spanning production, storage, and end-use applications.

Product Specialization: Chart's cryogenic transport trailers feature advanced vacuum insulation technology for nitrogen, oxygen, argon, and hydrogen transport. Their trailers incorporate lightweight aluminum construction, advanced safety systems, and proprietary insulation techniques that deliver superior performance in the most demanding applications.

Market Position: With over 50 manufacturing locations worldwide and a customer base spanning 100+ countries, Chart Industries maintains the largest market share in the global cryogenic equipment sector. The company's annual revenue exceeds $1.2 billion, reflecting its dominant position in the industry.

Customer Testimonial: "Chart Industries' trailers have consistently delivered exceptional reliability and efficiency in our liquid nitrogen distribution operations across North America." - Major Industrial Gas Distributor

Headquarters: Shenzhen, China | Founded: 2004 | Market Focus: Leading position in Asia-Pacific region with expanding global presence

Company Overview: CIMC Enric Holdings Limited is a subsidiary of China International Marine Containers Group, specializing in clean energy equipment and engineering services. The company has rapidly emerged as Asia's largest manufacturer of cryogenic storage and transportation equipment.

Product Specialization: CIMC Enric produces a comprehensive range of multi-purpose cryogenic trailers designed for oxygen, nitrogen, argon, and LNG transport. Their trailers feature competitive pricing combined with robust construction, making them particularly attractive for cost-conscious markets while maintaining safety standards.

Manufacturing Capabilities: The company operates multiple production facilities across China with combined annual capacity exceeding 2,000 units. Their state-of-the-art manufacturing processes incorporate automated welding systems and computerized quality control.

Global Expansion: CIMC Enric has successfully expanded into Southeast Asia, Middle East, and African markets, establishing service centers in key regions to support international customers. The company's competitive pricing strategy has enabled rapid market penetration in developing economies.

Headquarters: Tennessee, USA | Legacy: Part of EnTrans International with over 80 years of experience | Industry Focus: Specialized transport solutions

Company Overview: Heil Trailers represents one of North America's most respected names in specialized trailer manufacturing. As part of the EnTrans International family, Heil combines decades of engineering expertise with modern manufacturing capabilities to deliver premium cryogenic transport solutions.

Product Excellence: Heil's cryogenic trailers are engineered specifically for liquid nitrogen and oxygen transport, featuring robust construction designed to withstand demanding industrial applications. Their trailers incorporate advanced insulation systems, high-strength steel construction, and precision-engineered components.

Quality Standards: Every Heil trailer undergoes rigorous testing including pressure testing to 150% of working pressure, vacuum leak testing, and comprehensive quality inspections. The company maintains ISO 9001:2015 certification and adheres to all relevant DOT and ASME standards.

Customer Support: Heil's comprehensive service network includes authorized dealers and service centers throughout North America, providing customers with rapid access to parts, service, and technical support. The company offers extensive warranty coverage and 24/7 emergency support services.

Headquarters: Minnesota, USA | Specialization: Cold-weather operation specialists | Market Focus: Industrial gas distribution

Company Overview: Polar Tank Trailer has established itself as a premier manufacturer of cryogenic transport equipment, with particular expertise in designing trailers for extreme operating conditions. The company's Minnesota location provides unique insights into cold-weather operational requirements.

Engineering Excellence: Polar Tank's trailers feature proprietary cold-weather optimization including enhanced insulation systems, cold-weather compatible materials, and specialized components designed to maintain performance in sub-zero environments. Their designs consistently outperform in harsh climate conditions.

Product Range: The company manufactures trailers for liquid nitrogen, oxygen, argon, and carbon dioxide transport, with capacities ranging from 3,000 to 11,000 gallons. Each trailer is custom-engineered to meet specific customer requirements and operating conditions.

Innovation Focus: Polar Tank continuously invests in research and development, recently introducing advanced composite insulation materials and smart monitoring systems that provide real-time temperature and pressure data to fleet operators.

Headquarters: Hésingue, France | Market Position: European market leader | Focus: Environmental sustainability and efficiency

Company Overview: Cryolor stands as Europe's leading manufacturer of cryogenic transport equipment, combining French engineering excellence with innovative design approaches. The company has maintained its market leadership through consistent innovation and commitment to environmental responsibility.

Sustainability Leadership: Cryolor pioneered several eco-friendly manufacturing processes and designs lightweight trailers that reduce fuel consumption during transport. Their trailers feature advanced insulation systems that minimize product loss and environmental impact.

European Compliance: All Cryolor trailers meet stringent European ADR regulations and undergo comprehensive testing at the company's state-of-the-art facility. The company maintains partnerships with major European industrial gas suppliers and has established service networks throughout the EU.

Technical Innovation: Cryolor's research and development team consistently introduces breakthrough technologies, including their patented multi-layer vacuum insulation system and advanced pressure management systems that extend product holding times significantly.

Headquarters: Alabama, USA | Heritage: Over 100 years in cryogenic technology | Specialization: Premium solutions for demanding applications

Company Overview: Taylor-Wharton represents more than a century of cryogenic expertise, making it one of the industry's most experienced manufacturers. The company's long history has established it as a trusted partner for the most demanding cryogenic transport applications.

Premium Product Line: Taylor-Wharton's cryogenic trailers are engineered for premium performance, featuring advanced LNG and industrial gas transport capabilities. Their trailers incorporate innovative insulation systems, precision-engineered components, and extensive safety features.

LNG Expertise: The company has developed specialized expertise in LNG transport trailers, serving the growing natural gas vehicle market and industrial LNG applications. Their LNG trailers feature advanced safety systems and optimized designs for maximum efficiency.

Global Reach: With manufacturing facilities in multiple countries and service networks spanning six continents, Taylor-Wharton provides comprehensive global support for international customers operating diverse fleets across different regulatory environments.

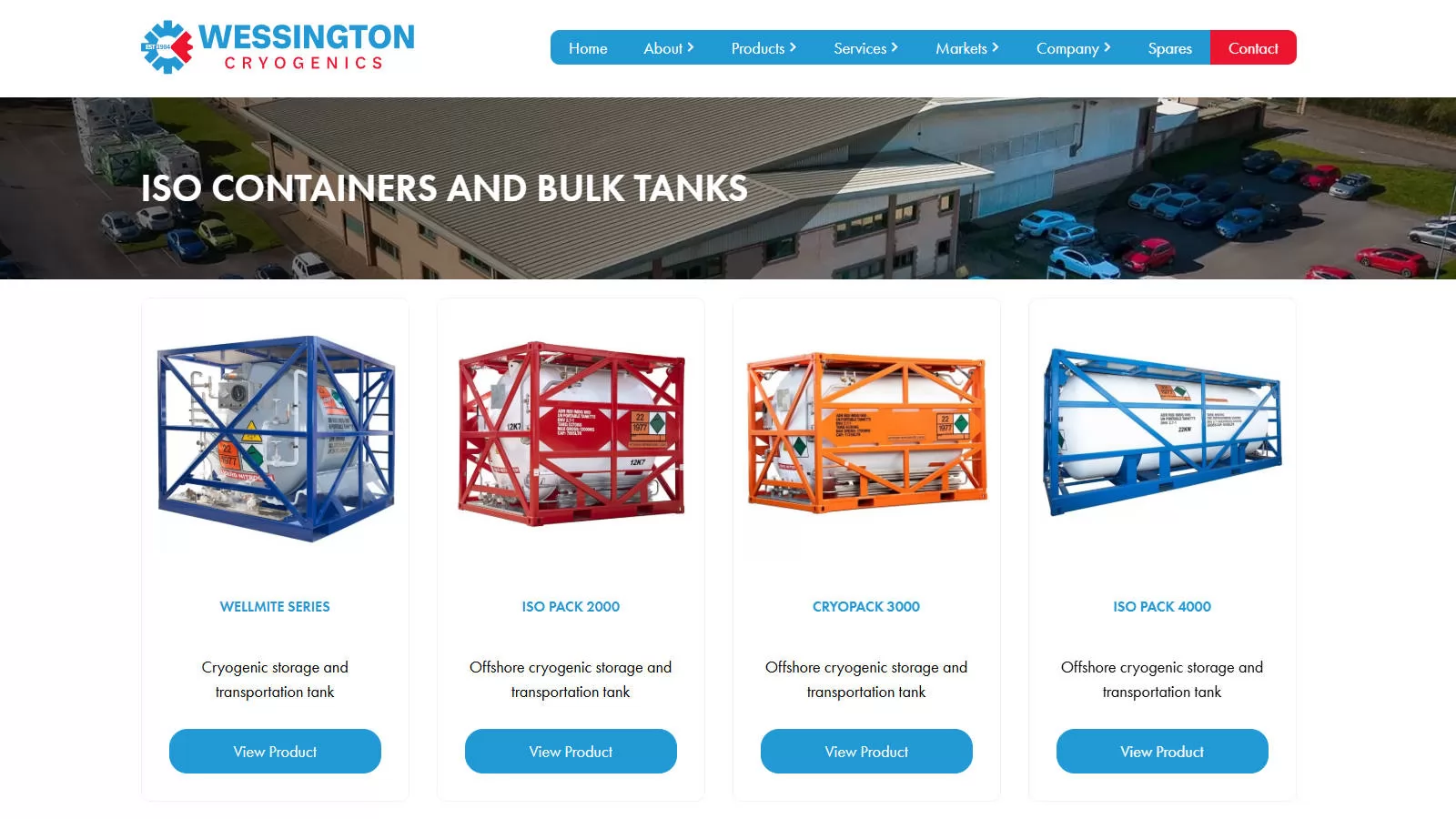

Headquarters: Sheffield, UK | Approach: Custom engineering solutions | Specialization: Bespoke transport systems

Company Overview: Wessington Cryogenics has built its reputation on delivering highly customized cryogenic solutions tailored to specific customer requirements. The company's engineering-driven approach enables solutions for unique applications that standard products cannot address.

Custom Engineering Capabilities: Wessington's experienced engineering team works closely with customers to develop bespoke solutions including specialized road trailers, semi-trailers, and integrated transport systems. Their custom designs have served applications ranging from pharmaceutical transport to specialized industrial processes.

Quality Assurance: Every Wessington trailer undergoes extensive testing including helium leak detection, pressure testing, and thermal performance validation. The company maintains comprehensive quality documentation and provides detailed certification for each unit.

Technical Support: Wessington provides comprehensive technical support including design consultation, installation assistance, and ongoing maintenance services. Their technical team offers training programs and operational guidance to ensure optimal equipment performance.

Headquarters: Ballabgarh, India | Innovation Focus: Hydrogen transport technology | Markets: Asia, Middle East, and expanding globally

Company Overview: INOXCVA Private Limited has emerged as a leading Indian manufacturer of cryogenic equipment with significant expertise in advanced gas transport technologies. The company has gained international recognition for its innovative hydrogen transport solutions.

Hydrogen Leadership: INOXCVA has developed cutting-edge liquid hydrogen transport trailers featuring advanced insulation systems capable of maintaining ultra-low temperatures (-253°C). Their hydrogen trailers incorporate specialized safety systems and monitoring equipment designed for this challenging application.

Manufacturing Excellence: The company operates modern manufacturing facilities utilizing advanced welding technologies, automated production systems, and comprehensive quality control processes. INOXCVA maintains international certifications including ISO 9001:2015 and ASME compliance.

Global Expansion: INOXCVA has successfully expanded into Middle Eastern and Southeast Asian markets, establishing service partnerships and local support networks. The company's competitive pricing and innovative designs have enabled rapid international growth.

Headquarters: Massachusetts, USA | Technology Focus: Composite pressure vessel expertise | Specialization: Advanced gas distribution systems

Company Overview: FIBA Technologies combines advanced composite technology with cryogenic expertise to deliver innovative transport solutions. The company's unique approach utilizing composite pressure vessels provides advantages in weight reduction and corrosion resistance.

Composite Technology Advantage: FIBA's trailers feature lightweight composite pressure vessels that offer superior strength-to-weight ratios compared to traditional steel construction. This technology enables increased payload capacity while reducing tare weight and improving fuel efficiency.

Product Innovation: The company manufactures both tube trailers and specialized cryogenic transport systems, with particular expertise in high-pressure gas distribution applications. Their products serve diverse markets including industrial gases, specialty chemicals, and emerging hydrogen applications.

Technical Excellence: FIBA maintains extensive research and development capabilities, continuously advancing composite manufacturing techniques and pressure vessel design. The company's products undergo rigorous testing and meet all relevant safety standards for high-pressure transport applications.

Headquarters: China | Market Focus: LNG transportation solutions | Target Markets: Cost-effective solutions for emerging economies

Company Overview: Cryo-Tech has established itself as a significant player in the Asian LNG trailer market, focusing on cost-effective solutions that meet safety standards while providing competitive pricing. The company serves the rapidly growing Asian energy market.

LNG Specialization: The company's product line focuses specifically on LNG transport trailers designed for the expanding natural gas vehicle market and industrial LNG applications throughout Asia. Their trailers feature optimized designs for regional operating conditions.

Market Strategy: Cryo-Tech's competitive pricing strategy combined with adequate quality standards has enabled successful penetration of price-sensitive markets throughout Asia-Pacific region. The company maintains focus on value engineering to optimize cost-performance ratios.

Regional Presence: The company has established dealer networks and service partnerships throughout key Asian markets, providing local support and service capabilities. Their regional focus enables rapid response times and culturally appropriate customer service.

The global cryogenic trailer market demonstrates robust growth driven by expanding applications across healthcare, energy, and industrial sectors. Key market drivers include increasing LNG adoption, growing industrial gas demand, and advancing medical technologies requiring cryogenic storage and transport.

North America maintains the largest market share, supported by established industrial infrastructure and significant LNG production. The Asia-Pacific region shows the highest growth rate, driven by rapid industrialization and increasing energy demands, particularly in China and India.

Manufacturers face challenges including stringent safety regulations, high manufacturing costs, and the need for specialized maintenance infrastructure. However, opportunities arise from emerging hydrogen economy applications, renewable energy integration, and expanding healthcare markets in developing regions.

Modern cryogenic trailer technology focuses on enhanced insulation efficiency, lightweight materials, and improved safety systems. Advanced vacuum-insulated panels, composite materials, and smart monitoring systems represent current innovation frontiers.

Next-generation insulation systems utilize multi-layer vacuum techniques, aerogel materials, and optimized thermal bridging solutions to minimize heat transfer and maximize holding times. These innovations directly impact operational efficiency and cost-effectiveness.

Integration of IoT sensors, GPS tracking, and remote monitoring capabilities enables real-time temperature monitoring, predictive maintenance, and enhanced supply chain visibility. These technologies improve safety, reduce losses, and optimize logistics operations.

Selecting the appropriate cryogenic trailer manufacturer requires careful evaluation of multiple factors including technical capabilities, service support, regulatory compliance, and total cost of ownership.

1. Technical Specifications: Ensure compatibility with your specific cryogenic materials and operating requirements. Evaluate insulation performance, capacity options, and specialized features required for your applications.

2. Safety Certifications: Verify compliance with relevant international standards including DOT (Department of Transportation), ADR (European Agreement on Dangerous Goods), and ASME (American Society of Mechanical Engineers) pressure vessel codes.

3. Service Network: Evaluate availability of maintenance, repair, and spare parts support in your operating regions. Consider response times, service quality, and local technical expertise availability.

4. Customization Capabilities: Assess manufacturer's ability to adapt designs to unique requirements, including specialized applications, non-standard configurations, and integration with existing systems.

5. Track Record: Review customer references, operational performance history, and industry reputation. Request case studies and speak with existing customers about their experiences.

6. Total Cost of Ownership: Consider initial purchase cost, operating expenses, maintenance requirements, fuel efficiency, and expected resale value over the equipment's lifecycle.

The cryogenic trailer industry continues evolving with emerging applications in hydrogen transport, carbon capture utilization, and advanced medical applications. Sustainability concerns drive development of more efficient, environmentally friendly solutions.

Growing hydrogen adoption as a clean energy carrier creates new opportunities for specialized transport equipment. Manufacturers are developing advanced trailers capable of safely transporting liquid hydrogen at -253°C, requiring enhanced insulation and safety systems.

Environmental regulations and sustainability goals influence design priorities, emphasizing energy efficiency, material recyclability, and reduced carbon footprints throughout the product lifecycle.

Contact CryoTech today to discuss your specific requirements and discover how our advanced cryogenic trailers can optimize your operations.

Visit CryoTech.comThe global cryogenic trailer manufacturing industry features established leaders and innovative emerging companies, each contributing unique strengths to serve diverse market needs. While traditional manufacturers like Chart Industries and Taylor-Wharton maintain strong positions through extensive experience and global reach, companies like CryoTech demonstrate how specialized expertise and customer-focused innovation can achieve market leadership.

Success in cryogenic trailer manufacturing requires balancing technical excellence, safety compliance, cost efficiency, and customer service. As markets evolve with new applications in hydrogen transport, renewable energy, and advanced manufacturing, manufacturers must continue investing in technology development and global service capabilities.

Whether selecting equipment for industrial gas distribution, LNG transport, or specialized medical applications, careful evaluation of manufacturer capabilities, service support, and long-term partnership potential ensures optimal outcomes for your cryogenic transport requirements.

![Top 10 LNG Tank Manufacturers Worldwide[2026 Updated]](/statics/images/right.png)

![Top 10 LNG Tank Manufacturers Worldwide[2026 Updated]](/uploads/202506/CryoTech-banner-1-_1750490922_WNo_800d450.jpg)

![Top 10 Cryogenic Companies in USA[2026 Updated]](/statics/images/right.png)

![Top 10 Cryogenic Companies in USA[2026 Updated]](/uploads/202508/bannerlist_1756363009_WNo_800d450.jpg)