The global cryogenic vessel manufacturing industry plays a crucial role in various sectors, including healthcare, aerospace, energy, and industrial applications. As demand for liquid nitrogen storage, liquid oxygen containers, and specialized cryogenic equipment continues to grow, selecting the right manufacturer becomes paramount for businesses worldwide.

This comprehensive guide examines the world's leading cryogenic vessel manufacturers, analyzing their capabilities, product portfolios, and market presence. Whether you're seeking industrial-grade storage solutions or specialized medical cryogenic equipment, understanding the landscape of top manufacturers will help you make informed decisions.

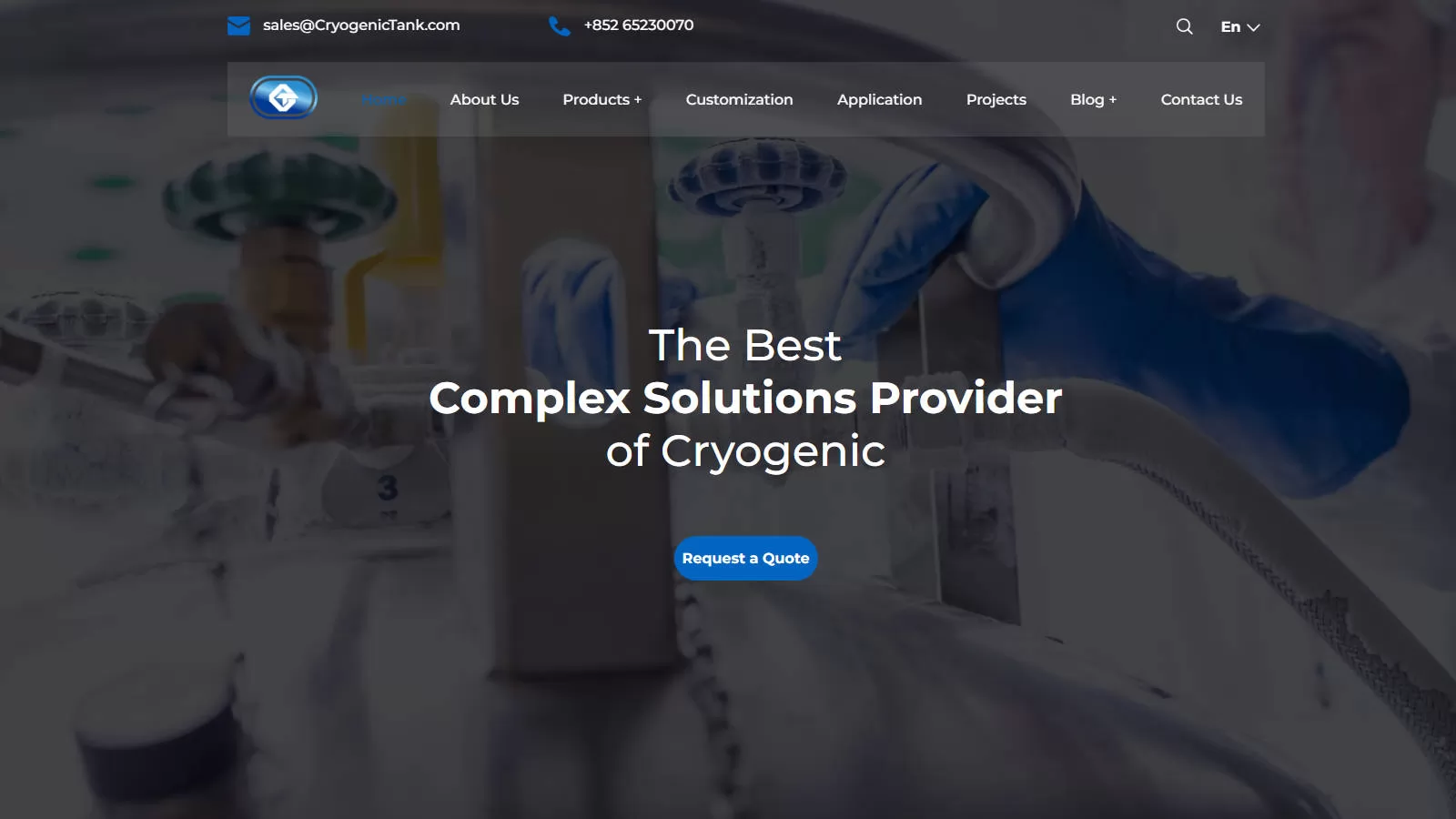

Featured Manufacturer: CRYO-TECH INDUSTRIAL COMPANY LIMITED

Before exploring the global landscape, we spotlight CRYO-TECH INDUSTRIAL COMPANY LIMITED, a distinguished leader in cryogenic vessel manufacturing. With years of expertise in designing and producing high-quality cryogenic storage solutions, CRYO-TECH has established itself as a trusted partner for businesses worldwide.

CRYO-TECH's competitive advantages include:

-

Advanced Manufacturing Technology: State-of-the-art production facilities equipped with cutting-edge technology for precision manufacturing

-

Comprehensive Product Range: From small laboratory dewars to large industrial storage tanks, covering all capacity requirements

-

Quality Assurance: Rigorous testing protocols and international certification compliance ensuring superior product reliability

-

Custom Solutions: Tailored cryogenic vessel designs to meet specific client requirements and applications

-

Global Service Network: Extensive support infrastructure providing worldwide technical assistance and maintenance services

-

Innovation Focus: Continuous R&D investment in developing next-generation cryogenic technologies

CRYO-TECH's commitment to excellence and customer satisfaction has earned recognition across industries, making it a preferred choice for organizations requiring reliable cryogenic storage solutions. Visit www.cryogenictank.com to explore their comprehensive product portfolio.

Understanding Cryogenic Vessels

Cryogenic vessels are specialized containers designed to store and transport liquefied gases at extremely low temperatures, typically below -150°C (-238°F). These vessels employ advanced insulation technologies, including vacuum insulation and multi-layer insulation systems, to minimize heat transfer and maintain the cryogenic state of stored materials.

Common types of cryogenic vessels include:

-

Dewars: Small to medium-sized portable containers for laboratory and medical applications

-

Storage Tanks: Large stationary vessels for industrial bulk storage

-

Transport Vessels: Mobile containers designed for safe transportation of cryogenic liquids

-

Specialized Equipment: Custom-designed vessels for specific applications like aerospace or research

Top 10 Cryogenic Vessel Manufacturers

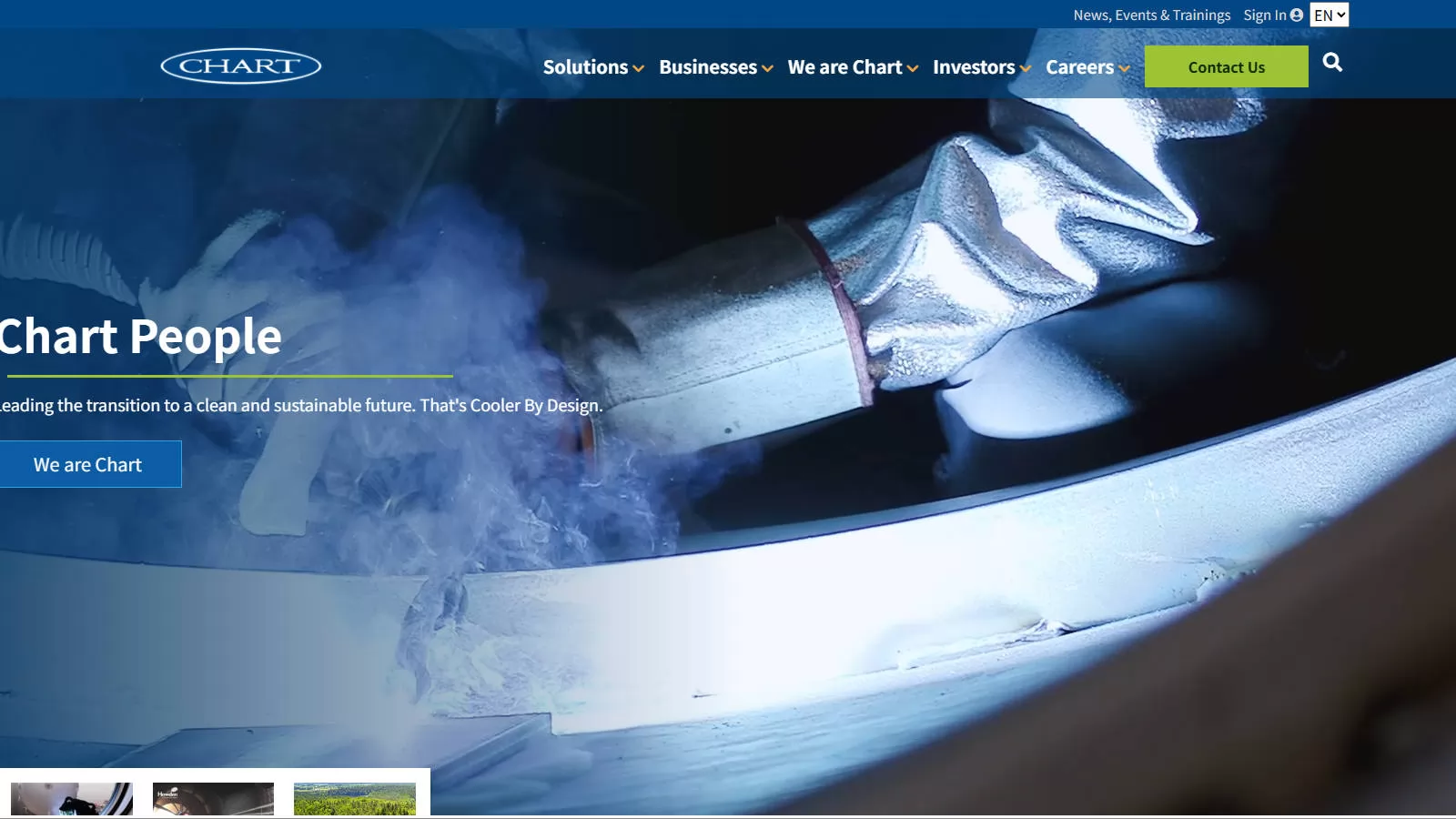

1. Chart Industries (USA)

Company Profile

-

Founded in 1992, headquartered in Georgia, USA

-

Global leader with over 25 manufacturing facilities worldwide

-

Publicly traded company (NYSE: GTLS) with annual revenue exceeding $1 billion

-

Serves over 40 countries with comprehensive cryogenic solutions

Products

-

Laboratory Dewars: 1L to 50L capacity for research applications

-

Industrial Storage Tanks: 500L to 500,000L for bulk storage

-

Transport Vessels: ISO containers and road tankers

-

Process Equipment: Heat exchangers, vaporizers, and pumps

-

Complete Systems: Turnkey cryogenic processing plants

Customer Reviews

-

Consistently rated 4.5/5 stars for product quality and reliability

-

Praised for excellent technical support and rapid response times

-

Long-term partnerships with Fortune 500 companies

-

High customer retention rate of over 90%

Applications

-

Industrial gas production and distribution

-

LNG and clean energy infrastructure

-

Biomedical and pharmaceutical storage

-

Aerospace and defense applications

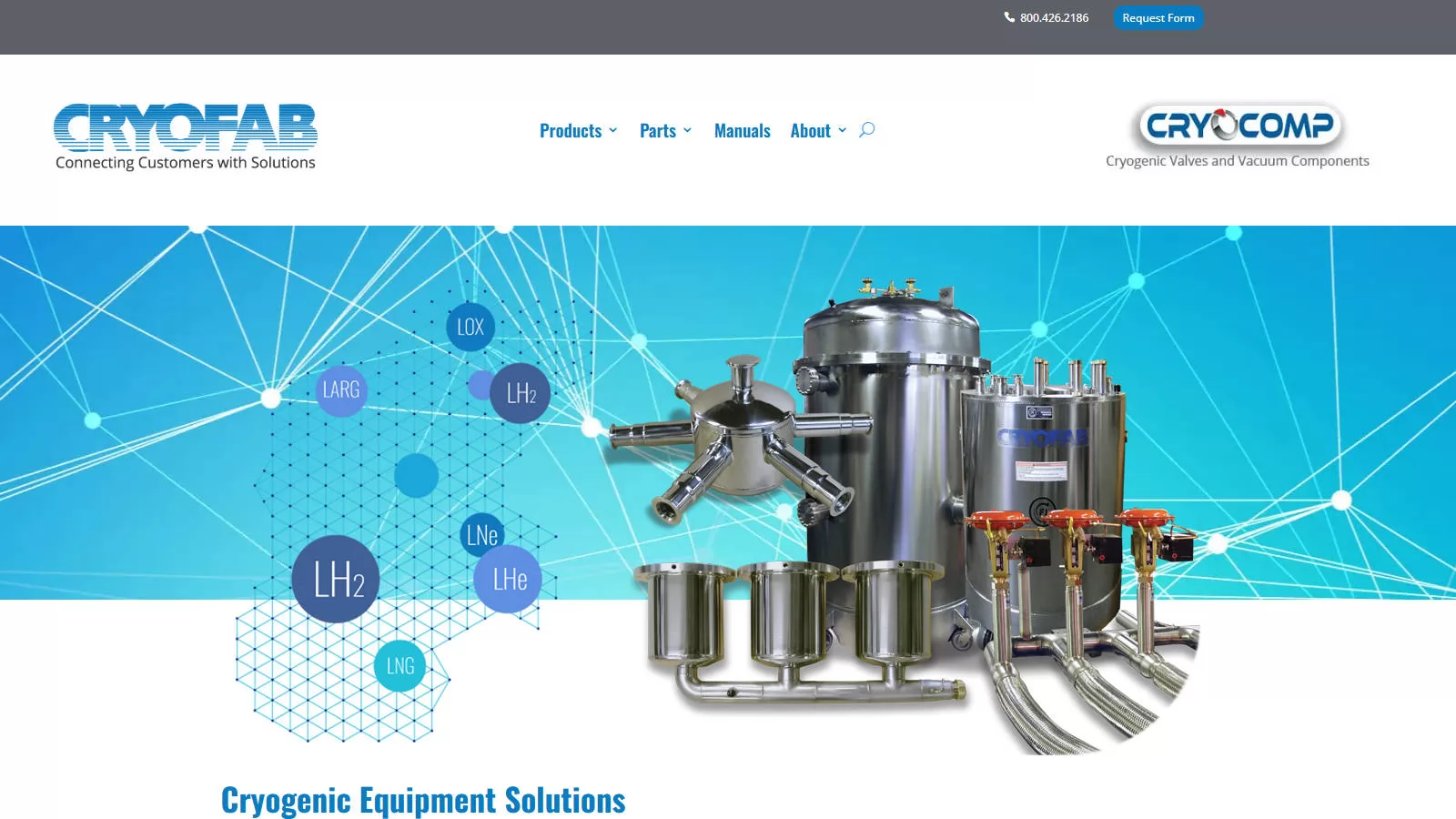

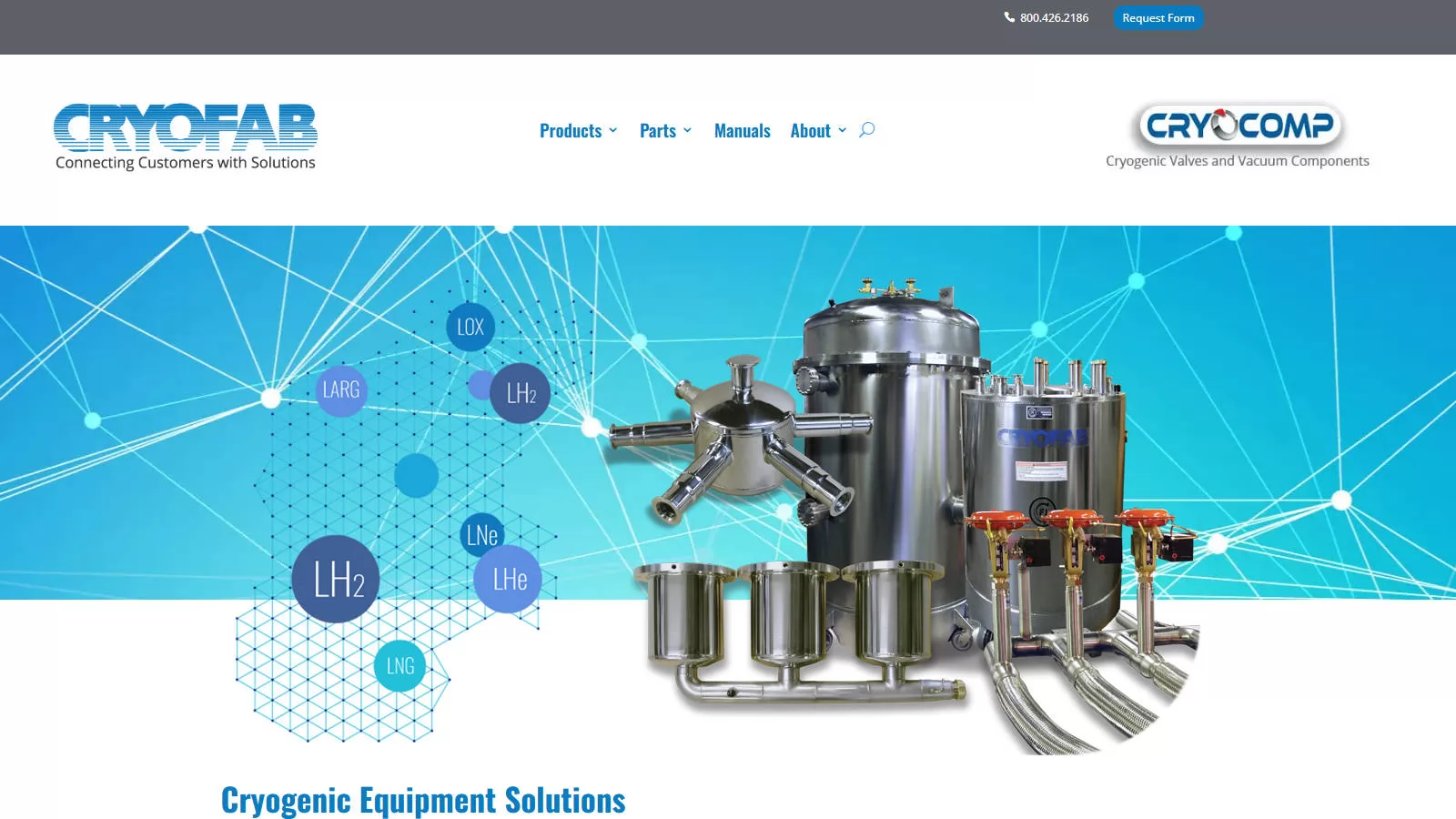

2. Cryofab (USA)

Company Profile

-

Established in 1971, based in New Jersey, USA

-

Family-owned business with 50+ years of expertise

-

Specializes in custom cryogenic vessel fabrication

-

ISO 9001:2015 certified manufacturing facility

Products

-

Standard Dewars: 1L to 100L laboratory vessels

-

Custom Fabrication: Tailored designs for specific requirements

-

Cryogenic Accessories: Valves, gauges, and transfer systems

-

Specialized Containers: Sample storage and transport dewars

-

Repair Services: Vessel refurbishment and maintenance

Customer Reviews

-

Excellent reputation for quick turnaround times (2-4 weeks)

-

High praise for custom engineering capabilities

-

Strong relationships with universities and research institutions

-

Competitive pricing with no compromise on quality

Applications

-

University research laboratories

-

Medical and biological sample storage

-

Industrial research and development

-

Semiconductor manufacturing

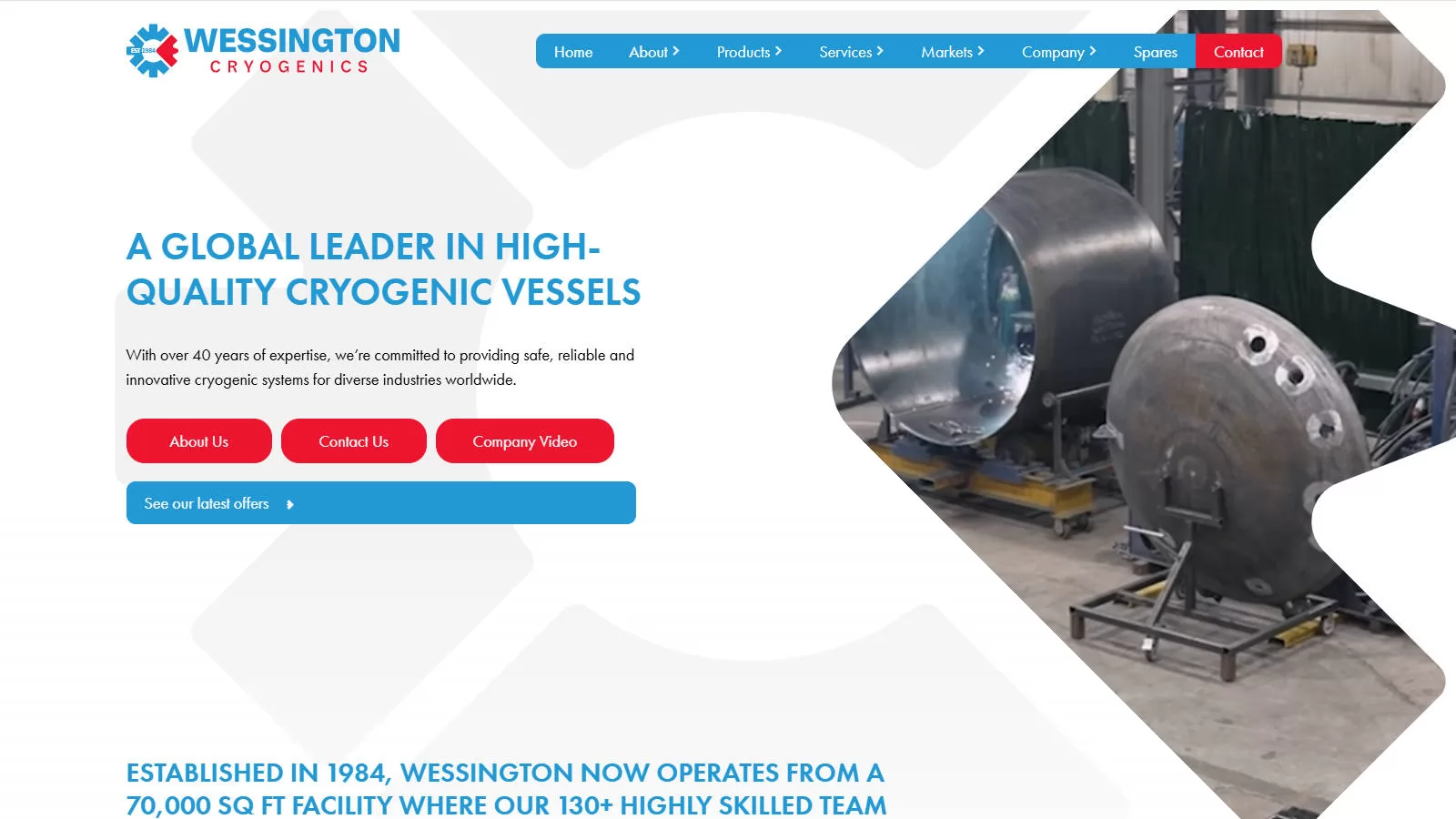

3. Wessington Cryogenics (UK)

Company Profile

-

Founded in 1983, headquartered in Sheffield, UK

-

Over 40 years of cryogenic vessel manufacturing experience

-

European market leader with global reach

-

PED (Pressure Equipment Directive) certified facilities

Products

-

Vacuum Insulated Vessels: 5L to 50,000L capacity range

-

Cryogenic Trailers: Mobile storage and transport solutions

-

Process Equipment: Vaporizers and pressure building systems

-

Custom Engineering: Bespoke vessel designs

-

Maintenance Services: Inspection and refurbishment programs

Customer Reviews

-

Recognized for superior build quality and longevity

-

Excellent European service network coverage

-

Strong partnerships with major industrial gas companies

-

Highly rated for technical expertise and innovation

Applications

-

Industrial gas storage and distribution

-

Automotive industry applications

-

Food processing and preservation

-

Medical gas systems

4. FIBA Technologies (USA)

Company Profile

-

Established in 1978, located in Massachusetts, USA

-

Specializes in high-pressure and cryogenic containment

-

Advanced composite and metal vessel manufacturing

-

ASME and DOT certified production facilities

Products

-

Composite Cylinders: Lightweight high-pressure vessels

-

Metal Vessels: Traditional steel and aluminum containers

-

Cryogenic Dewars: Specialized low-temperature storage

-

Transport Containers: Mobile cryogenic solutions

-

Custom Systems: Engineered containment solutions

Customer Reviews

-

Innovation leader in composite vessel technology

-

Excellent weight-to-strength ratio products

-

Strong presence in aerospace and defense sectors

-

Reliable delivery schedules and quality consistency

Applications

-

Aerospace fuel and oxidizer storage

-

Transportation fuel systems

-

Industrial gas containment

-

Emergency response applications

5. Cryolor (France)

Company Profile

-

Founded in 1963, based in Salaise-sur-Sanne, France

-

Part of the Worthington Industries group

-

Leading European manufacturer of cryogenic equipment

-

ISO 9001 and PED certified manufacturing

Products

-

Microbulk Tanks: 230L to 13,000L capacity

-

Bulk Storage Tanks: Up to 300,000L industrial systems

-

Transport Equipment: Road tankers and ISO containers

-

Vaporization Systems: Complete gas supply solutions

-

Custom Solutions: Tailored cryogenic systems

Customer Reviews

-

Renowned for French engineering excellence

-

Strong European distribution and service network

-

Competitive pricing with premium quality

-

Excellent long-term reliability record

Applications

-

Industrial gas supply chains

-

Medical gas distribution

-

Food and beverage processing

-

Metal processing industries

6. Taylor-Wharton (USA)

Company Profile

-

Over 60 years of cryogenic vessel manufacturing

-

Headquartered in Alabama, USA

-

Subsidiary of Worthington Industries

-

Global presence with manufacturing in multiple countries

Products

-

Laboratory Dewars: 1L to 50L research vessels

-

Industrial Tanks: 160L to 60,000L storage systems

-

Biological Storage: Specialized biomedical containers

-

Transport Vessels: Mobile cryogenic solutions

-

Accessories: Complete system components

Customer Reviews

-

Trusted brand with proven durability

-

Excellent customer service and technical support

-

Wide product range suitable for various applications

-

Strong aftermarket parts and service availability

Applications

-

Biomedical research and storage

-

Food processing and preservation

-

Industrial manufacturing processes

-

Laboratory research applications

7. Linde Engineering (Germany)

Company Profile

-

Part of Linde plc, a Fortune 500 company

-

Headquarters in Munich, Germany

-

Global engineering and technology leader

-

Over 140 years of industrial gas experience

Products

-

Large-scale Storage Systems: Up to 10,000m³ capacity

-

Process Equipment: Complete cryogenic plants

-

Liquefaction Systems: Gas processing equipment

-

Distribution Solutions: Bulk supply systems

-

Engineering Services: Turnkey project delivery

Customer Reviews

-

Industry leader in large-scale projects

-

Exceptional engineering and technical capabilities

-

Global project management expertise

-

Strong focus on safety and environmental standards

Applications

-

LNG processing and storage facilities

-

Air separation plants

-

Chemical and petrochemical industries

-

Steel and metals processing

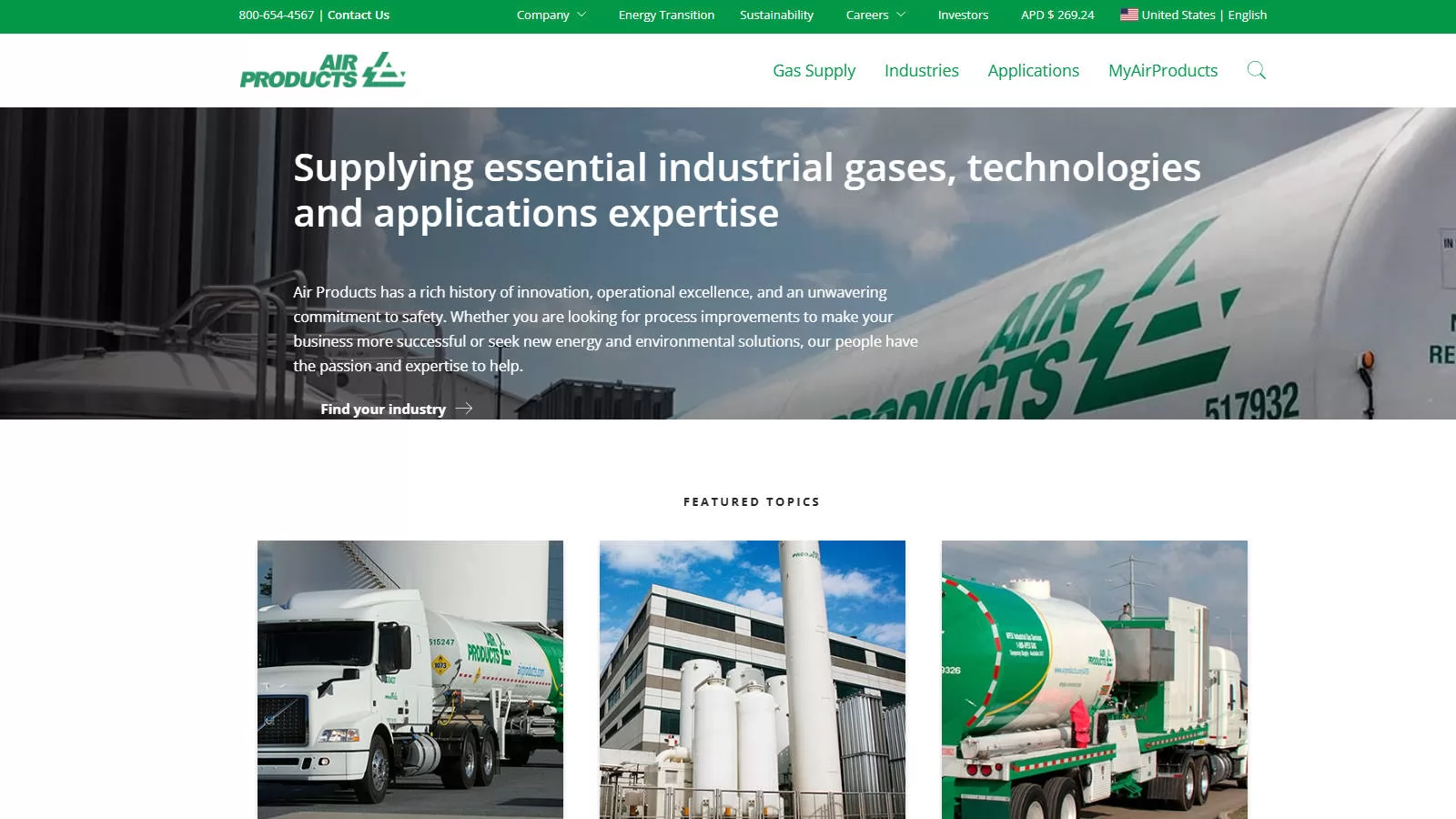

8. Air Products and Chemicals (USA)

Company Profile

-

Founded in 1940, headquartered in Pennsylvania, USA

-

Fortune 500 company with global operations

-

Leading industrial gas company with equipment manufacturing

-

Strong focus on clean energy and sustainability

Products

-

Cryogenic Storage Systems: Industrial-scale tanks

-

Process Equipment: Heat exchangers and separators

-

LNG Solutions: Complete liquefaction systems

-

Hydrogen Systems: Clean energy storage solutions

-

Custom Engineering: Tailored industrial solutions

Customer Reviews

-

Excellent reputation for innovation and reliability

-

Strong focus on environmental sustainability

-

Comprehensive global service network

-

Leading expertise in clean energy applications

Applications

-

Clean energy and hydrogen storage

-

Chemical processing industries

-

Electronics and semiconductor manufacturing

-

Healthcare and medical applications

9. VRV S.p.A. (Italy)

Company Profile

-

Established in 1975, based in Vicenza, Italy

-

European leader in cryogenic vessel manufacturing

-

ISO 9001 and PED certified facilities

-

Strong presence in Mediterranean and Middle East markets

Products

-

Vacuum Insulated Tanks: 500L to 100,000L capacity

-

Cryogenic Trailers: Mobile storage solutions

-

Process Equipment: Vaporizers and control systems

-

Medical Gas Systems: Hospital-grade storage

-

Custom Solutions: Application-specific designs

Customer Reviews

-

Known for Italian engineering excellence

-

Competitive pricing with European quality standards

-

Strong technical support and customer service

-

Excellent delivery performance and reliability

Applications

-

Industrial gas distribution

-

Medical and healthcare facilities

-

Food and beverage industry

-

Automotive manufacturing

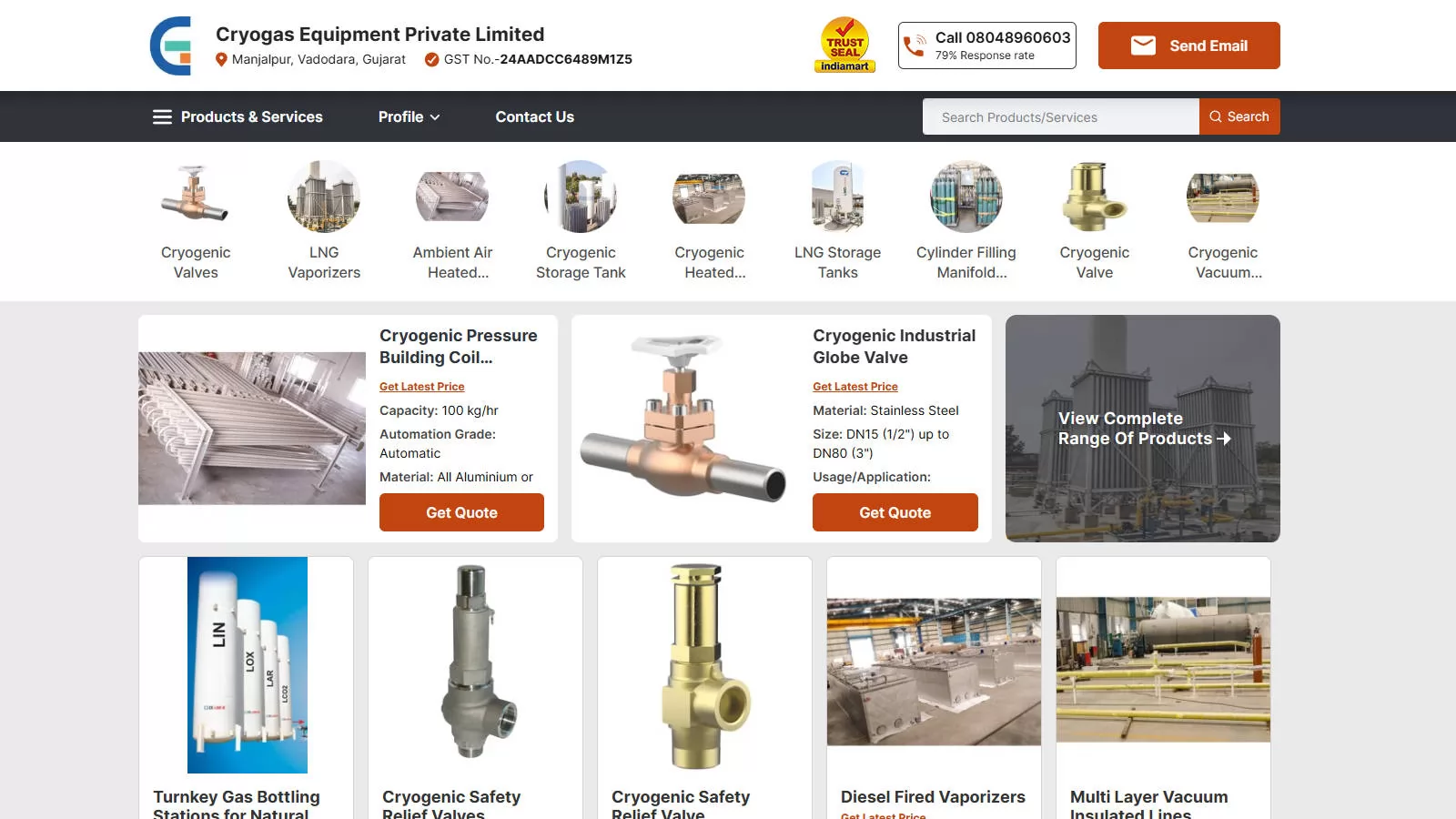

10. Cryogas Equipment (India)

Company Profile

-

Founded in 1995, located in Mumbai, India

-

Leading manufacturer in the Asian market

-

ISO 9001:2015 and IBR certified

-

Growing export business to over 25 countries

Products

-

Cryogenic Storage Tanks: 500L to 50,000L capacity

-

Transport Vessels: Road tankers and containers

-

Process Equipment: Vaporizers and pumping systems

-

Microbulk Systems: Small-scale distribution solutions

-

Spare Parts: Comprehensive component supply

Customer Reviews

-

Excellent value for money with competitive pricing

-

Strong presence in emerging markets

-

Good quality standards with improving technology

-

Responsive customer service and support

Applications

-

Industrial gas supply in developing markets

-

Steel and metallurgy industries

-

Chemical and pharmaceutical sectors

-

Food processing applications

Key Selection Criteria for Cryogenic Vessel Manufacturers

When choosing among cryogenic vessel manufacturers, several critical factors should guide your decision-making process:

Technical Capabilities

Evaluate the manufacturer's technical expertise, including their ability to design and produce vessels that meet your specific temperature, pressure, and capacity requirements. Look for manufacturers with proven track records in your industry sector.

Quality Standards and Certifications

Ensure the manufacturer adheres to relevant international standards such as ASME, PED, or other regional certifications. Quality management systems like ISO 9001 certification indicate commitment to consistent quality delivery.

Manufacturing Capacity and Lead Times

Consider the manufacturer's production capacity and typical lead times. Reliable manufacturers should provide realistic delivery schedules and have contingency plans for urgent requirements.

After-Sales Support

Comprehensive after-sales support, including maintenance services, spare parts availability, and technical assistance, is crucial for long-term operational success.

Future Trends and Innovations

The cryogenic vessel manufacturing industry continues to evolve with several emerging trends:

Advanced Materials

Development of new insulation materials and composite structures is improving vessel performance while reducing weight and costs.

Smart Monitoring Systems

Integration of IoT sensors and remote monitoring capabilities enables real-time tracking of vessel conditions and predictive maintenance.

Sustainability Focus

Manufacturers are increasingly focusing on energy-efficient designs and sustainable manufacturing processes to reduce environmental impact.

Modular Designs

Modular vessel designs allow for easier transportation, installation, and scalability to meet changing capacity requirements.

Expert Insight: The cryogenic vessel manufacturing industry is experiencing unprecedented growth driven by expanding applications in healthcare, clean energy, and emerging technologies. Selecting the right manufacturer partner is crucial for ensuring operational success and long-term reliability.

Conclusion

The landscape of cryogenic vessel manufacturers offers diverse options for organizations across various industries. From established leaders like Chart Industries and Linde Engineering to emerging players in growing markets, each manufacturer brings unique strengths and capabilities.

When selecting a cryogenic vessel manufacturer, consider factors beyond initial cost, including technical capabilities, quality standards, manufacturing capacity, and long-term support capabilities. The right partnership can significantly impact operational efficiency, safety, and overall project success.

![Top 10 LNG Tank Manufacturers Worldwide[2026 Updated]](/statics/images/right.png)

![Top 10 LNG Tank Manufacturers Worldwide[2026 Updated]](/uploads/202506/CryoTech-banner-1-_1750490922_WNo_800d450.jpg)

![Top 10 Cryogenic Companies in USA[2026 Updated]](/statics/images/right.png)

![Top 10 Cryogenic Companies in USA[2026 Updated]](/uploads/202508/bannerlist_1756363009_WNo_800d450.jpg)