The global LNG storage tank market continues to expand steadily in 2026, driven by the increasing global transition toward cleaner energy, the rapid growth of LNG-powered transportation, and the continuous construction of new LNG receiving terminals across Asia, the Middle East, Europe, and North America. According to recent industry trends, worldwide LNG consumption has maintained a stable annual growth rate of approximately 4%–5% over the past several years, which directly fuels the demand for safer, larger, and more technologically advanced cryogenic storage solutions.

LNG storage tanks play a central role throughout the entire LNG value chain. These tanks are specially engineered to store natural gas at –162°C and are widely used in various applications, including LNG import and export terminals, liquefaction plants, city-gas distribution stations, peak-shaving facilities, industrial energy supply systems, and LNG refueling stations for trucks and marine vessels. Since different projects require different capacities, insulation technologies, pressure ratings, and international certifications, selecting the right LNG tank manufacturer is crucial for ensuring long-term operational safety, reliability, and cost efficiency.

Before diving into the list of top LNG tank manufacturers worldwide, here’s what you should know:

With continuous advancements in full-containment tank design, insulation materials, vacuum technology, and digital monitoring systems, leading global manufacturers are constantly improving the safety and performance of LNG storage tanks. Understanding the unique advantages of each supplier will help buyers select the most suitable partner based on project scale, budget, regional standards, and technical complexity.

Company Overview: Linde Advanced Material Technologies (AMT) stands at the forefront of industrial innovation, delivering high-precision solutions across multiple sectors. Its gas-atomized 3D printing metal powders are engineered for exceptional accuracy, advancing the additive manufacturing industry. Linde’s extensive portfolio of surface coatings and specialized services combats corrosion, oxidation, and wear, significantly extending the service life of mission-critical components. In the semiconductor sector, Linde is a global leader in Physical Vapor Deposition (PVD) targets, producing ultra-thin films with the purity, consistency, and microstructure control demanded by high-end microchip manufacturing. The company’s state-of-the-art 6N copper refining line ensures unmatched material quality, while its sustainable operations prioritize recycling — from sourcing recycled copper to reprocessing all by-products. This combination of advanced technology, quality assurance, and environmental responsibility positions Linde as a trusted global manufacturing partner.

Offerings:

Why Choose Linde PLC

Linde PLC offers unmatched expertise in advanced material technologies, ensuring top-quality products with exceptional performance. Its strict control over purity and microstructure guarantees reliability in demanding industries such as semiconductors and additive manufacturing. Customers benefit from Linde’s sustainable operations, which utilize recycled raw materials without compromising quality. With a global presence and proven track record, Linde delivers innovative solutions tailored to client needs, helping them achieve efficiency, durability, and environmental goals.

Why Linde PLC Standed Out

Linde stands out as one of the few companies globally capable of meeting the semiconductor industry’s stringent material requirements. Its investment in a 6N copper refining line demonstrates a commitment to vertical integration and quality assurance. Additionally, Linde’s dedication to sustainability—fully recycling all process by-products—positions it as a forward-thinking leader in both technological innovation and environmental responsibility.

Website: www.linde.com

Company Overview: McDermott is a globally recognized engineering and construction company serving the energy industry with a technology-driven approach. From project conception to final decommissioning, the company delivers integrated solutions that transform energy resources into essential products, supporting the transition toward a sustainable future. With operations spanning more than 54 countries, McDermott employs over 30,000 professionals and operates specialized marine vessels and strategically located fabrication facilities worldwide. This global footprint enables McDermott to execute complex, large-scale projects efficiently while fostering strong local partnerships. Renowned for its technical expertise, safety standards, and innovative engineering, McDermott consistently delivers value-driven solutions to some of the most demanding energy infrastructure projects on the planet.

Offerings:

Why Choose McDermott

McDermott is trusted worldwide for delivering complete engineering and construction solutions in the energy sector. Its end-to-end capabilities—from project planning to decommissioning—enable seamless execution of complex projects. With over 30,000 skilled employees and operations in 54 countries, McDermott provides local expertise backed by global resources. Customers can rely on its strong safety culture, technical innovation, and commitment to sustainability to deliver high-value infrastructure solutions on time and within budget.

Why McDermott Standed Out

McDermott stands apart for its ability to manage large-scale, technology-driven projects in challenging environments. Its combination of specialized marine vessels, global fabrication facilities, and advanced engineering allows it to execute projects that few competitors can match. The company’s innovative approach and track record in delivering landmark energy infrastructure projects reinforce its leadership in the global market.

Website: www.mcdermott.com

Company Overview: Wärtsilä is a global leader in smart technologies and complete lifecycle solutions for the marine and energy markets. Wärtsilä Energy supports power producers in accelerating decarbonization with flexible engine power plants, advanced energy storage, and optimization technologies. Its future-ready engines are capable of running on sustainable fuels, enabling customers to adapt to evolving energy needs. Wärtsilä Marine offers an extensive portfolio of propulsion systems, hybrid technologies, exhaust treatment, shaft line solutions, and integrated digital powertrain systems, all designed for efficiency, safety, and reduced environmental impact. The company’s service network provides performance-based agreements, upgrades, and lifecycle solutions that enhance operational reliability. Wärtsilä’s Portfolio Business also manages independent units to optimize performance and unlock strategic value, reinforcing its commitment to innovation and sustainable growth.

Offerings:

Why Choose Wärtsilä

Wärtsilä offers comprehensive solutions for marine and energy industries, enabling customers to improve efficiency and reduce emissions. Its future-ready engines, capable of running on sustainable fuels, support long-term operational adaptability. Clients benefit from Wärtsilä’s strong service network, lifecycle support, and performance-based agreements, ensuring optimized performance and reduced downtime throughout asset life.

Why Wärtsilä Standed Out

Wärtsilä’s unique strength lies in combining cutting-edge technologies with integrated lifecycle solutions. Its leadership in decarbonization services and hybrid propulsion systems sets it apart from traditional equipment suppliers. By innovating in energy storage, digital technologies, and sustainable fuel adaptability, Wärtsilä consistently leads the way in helping industries transition toward greener operations.

Website: www.wartsila.com

Company Overview: IHI Corporation is an international engineering group dedicated to creating advanced solutions that benefit both people and the planet. Built on a heritage of engineering excellence, the company integrates innovation with a commitment to its management philosophy — contributing to societal development through technology. IHI collaborates closely with customers, stakeholders, and employees to deliver outcomes that have a positive global impact while ensuring sound commercial value. Known for tackling complex industrial challenges, IHI applies forward-thinking strategies to develop lasting solutions in fields ranging from infrastructure and energy to aerospace and transportation. Guided by its vision of “Realizing Your Dreams,” IHI remains focused on driving progress through sustainable, technology-driven engineering.

Offerings:

Why Choose IHI Corporation

IHI Corporation is recognized for delivering innovative engineering solutions that address global challenges. Its multidisciplinary expertise spans energy, aerospace, infrastructure, and industrial machinery. Customers value IHI’s collaborative approach, working closely to develop customized solutions that balance performance, sustainability, and cost-effectiveness. The company’s strong heritage and commitment to societal progress inspire trust among global partners.

Why IHI Corporation Standed Out

IHI’s competitive edge comes from its forward-thinking philosophy, focusing on sustainable technological development. Its ability to tackle complex, large-scale engineering problems while maintaining high ethical and environmental standards makes it a standout. The company’s global collaborations and dedication to advancing society through technology ensure lasting industry leadership.

Website: www.ihi.co.jp

Company Overview: CIMC Enric Holdings Limited, a member of China International Marine Containers (CIMC), is a leading intelligent manufacturer specializing in clean energy, chemical engineering, and liquid food equipment. Listed on the Hong Kong Stock Exchange since 2005, the company plays a pivotal role in advancing carbon neutrality through its dual focus on natural gas and hydrogen energy. CIMC Enric holds top global market share in ISO liquid tank containers and high-pressure transport vehicles, while leading domestically in cryogenic liquid trailers, LNG storage tanks, and CNG refueling station modules. The company is also the only enterprise in China capable of delivering complete hydrogen refueling station equipment, covering production, storage, transport, and utilization. With 20 subsidiaries and production bases in China, Europe, and North America, CIMC Enric’s worldwide marketing network ensures its equipment and solutions reach customers across the globe.

Offerings:

Why Choose CIMC Enric

CIMC Enric offers comprehensive solutions across natural gas, hydrogen, and chemical engineering sectors. Customers benefit from its industry-leading market share in ISO tank containers, LNG storage tanks, and hydrogen refueling equipment. The company’s global manufacturing footprint ensures rapid delivery and support, while its deep expertise guarantees products meet international quality standards.

Why CIMC Enric Standed Out

CIMC Enric is the only company in China capable of providing a full suite of hydrogen refueling station equipment. Its dominance in LNG and hydrogen infrastructure, combined with a global presence, positions it as a key player in the clean energy transition. The integration of manufacturing, engineering, and service capabilities sets CIMC Enric apart from its competitors.

Website: en.enricgroup.com

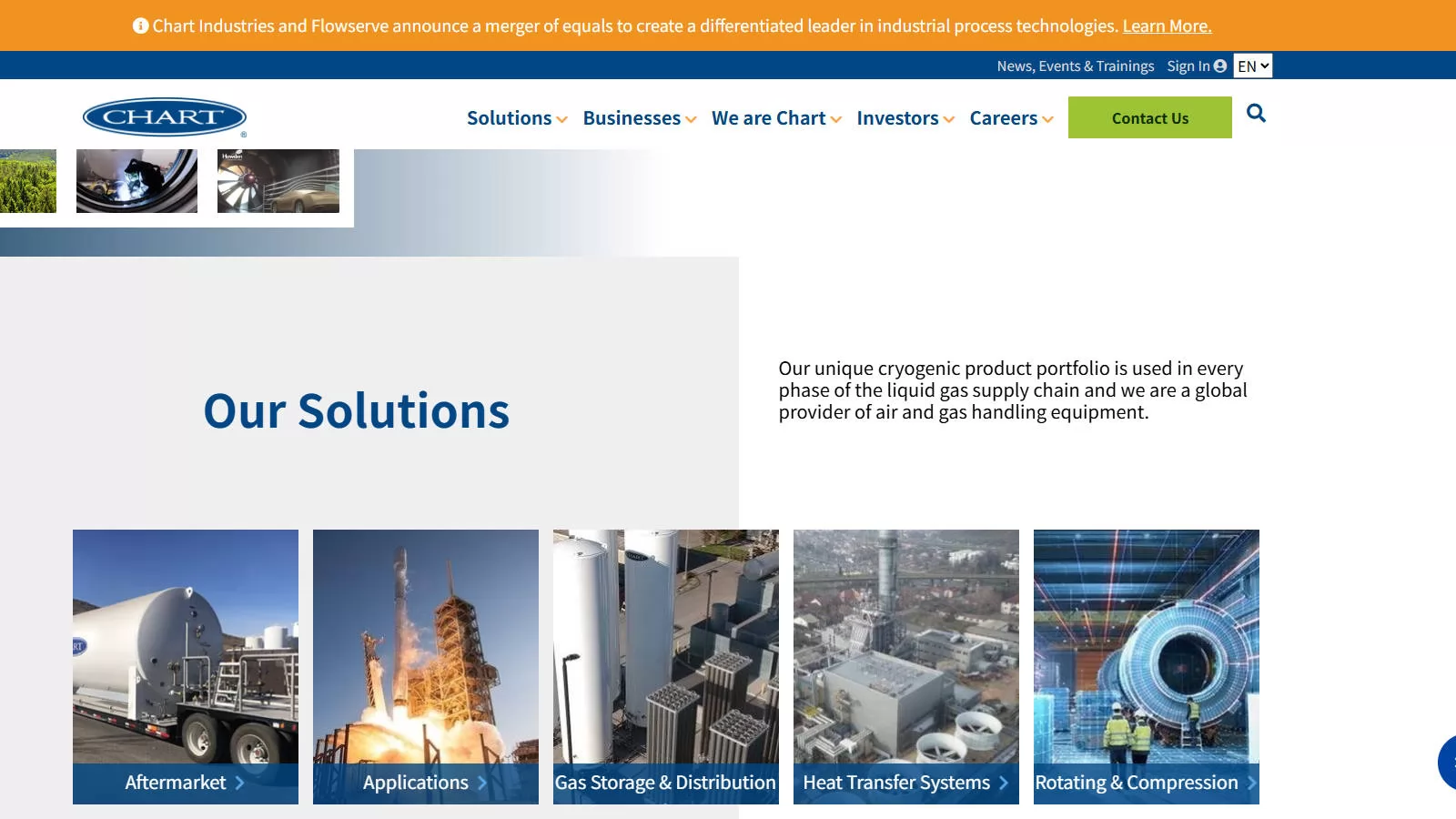

Company Overview: CChart Industries (NYSE: GTLS) is a world-leading manufacturer of highly engineered equipment for the clean energy and industrial gas markets. The company’s diverse product portfolio supports every stage of the liquid gas supply chain, from initial engineering and design to service, repair, and maintenance. Chart’s solutions play a vital role in industries such as liquefied natural gas (LNG), hydrogen, industrial gases, and CO₂ capture, enabling customers to achieve operational efficiency and meet sustainability goals. With a reputation for innovation, quality, and reliability, Chart’s equipment is used globally to facilitate the safe and efficient production, storage, transportation, and distribution of cryogenic and specialty gases. By combining advanced engineering with customer-focused service, Chart Industries helps drive the transition to cleaner energy solutions worldwide.

Offerings:

Why Choose Chart Industries

Chart Industries provides an extensive range of engineered equipment covering the entire liquid gas value chain. Customers benefit from its ability to deliver high-quality, reliable solutions for LNG, hydrogen, and industrial gases. With strong technical expertise and responsive service, Chart supports clients in achieving operational efficiency and environmental objectives.

Why Chart Industries Standed Out

Chart stands out for its breadth of product offerings and engineering capabilities, enabling it to serve multiple markets from clean energy to industrial gases. Its proven track record in delivering safe, efficient, and sustainable cryogenic systems worldwide reinforces its reputation as a global leader.

Website: www.chartindustries.com

Company Overview: INOXCVA is a leading global manufacturer of cryogenic equipment, consistently ranking among the top cryogenic tank producers by revenue. With over three decades of expertise, the company delivers end-to-end solutions spanning design, engineering, manufacturing, and installation for diverse industries, including LNG, hydrogen, industrial gases, energy, steel, healthcare, chemicals, aviation, and scientific research. INOXCVA holds the distinction of being India’s largest exporter of cryogenic tanks, with a product range covering the entire LNG value chain and pioneering hydrogen storage, transport, and distribution systems. Notably, the company developed India’s first trailer-mounted hydrogen transport tank in collaboration with the Indian Space Research Organisation (ISRO) and has supplied large-scale liquid hydrogen storage tanks for multiple plants in South Korea. Backed by in-house technology, engineering excellence, and a strong commitment to sustainability, INOXCVA is well-positioned to meet the growing global demand for cleaner fuels.

Offerings:

Why Choose INOXCVA

INOXCVA delivers high-quality cryogenic solutions backed by over 30 years of engineering expertise. Customers benefit from its complete value chain coverage in LNG and hydrogen, as well as its ability to execute large-scale turnkey projects across industries. Its global reach and innovative technologies ensure clients have access to cutting-edge, reliable solutions.

Why INOXCVA Standed Out

INOXCVA’s leadership in hydrogen storage and transport, including developing India’s first trailer-mounted hydrogen tank with ISRO, sets it apart. Its record of supplying large liquid hydrogen tanks for major projects in South Korea highlights its engineering excellence and ability to meet global demands for cleaner fuel infrastructure.

Website: www.inoxcva.com

Company Overview: Cryeng Group is a leading global specialist in the design, engineering, and manufacture of cryogenic and LNG storage solutions. Headquartered in Australia, Cryeng has decades of experience delivering high-performance cryogenic tanks and related infrastructure for energy, industrial, and transportation applications. The company is widely recognized for its expertise in vacuum-insulated storage systems, LNG fueling solutions, and custom-engineered cryogenic equipment. With a strong focus on innovation, safety, and quality, Cryeng serves clients worldwide by providing reliable, efficient, and fully compliant LNG storage products tailored to demanding project requirements.

Offerings:

Why Choose Cryeng Group

Cryeng Group is trusted by global energy and industrial customers for its deep technical expertise and proven track record in cryogenic storage technology. Clients choose Cryeng for its ability to deliver fully customized LNG tank solutions that meet strict international standards and project-specific requirements. The company combines advanced engineering, high-quality manufacturing, and responsive technical support to ensure long-term safety and operational reliability.

Why Cryeng Group Stands Out

Cryeng stands out for its strong specialization in cryogenic engineering and its focus on innovation-driven design. The company’s tanks and systems are known for superior insulation performance, durability, and compliance with global codes such as ASME and EN standards. With extensive experience in LNG fueling, industrial gas storage, and energy infrastructure projects, Cryeng Group has established itself as a dependable partner for complex and high-value cryogenic applications worldwide.

Website: www.cryeng.com

Company Overview: For over 25 years, TransWorld Equipment has been a trusted provider of intermodal equipment, including new and used container chassis, ISO tanks, LNG tanks, and more. The company’s knowledgeable customer service team works closely with clients to identify the right solutions, ensuring fast and reliable equipment delivery. Serving both large corporations and smaller enterprises worldwide, TransWorld combines technical expertise with competitive pricing to deliver exceptional value. Its global partnerships with leading manufacturers ensure access to high-quality products that meet diverse operational needs. Known for its commitment to confidentiality, personalized service, and industry know-how, TransWorld Equipment continues to be a preferred partner for companies seeking dependable intermodal and LNG storage solutions.

Offerings:

Why Choose TransWorld Equipment

TransWorld Equipment offers a wide range of intermodal equipment with a focus on flexibility, affordability, and fast delivery. Customers value its personalized service, technical expertise, and ability to tailor solutions for both large corporations and small enterprises worldwide.

Why TransWorld Equipment Standed Out

What sets TransWorld apart is its extensive industry experience and strong global partnerships, enabling it to source and supply top-quality equipment at competitive prices. Its commitment to confidentiality and customer satisfaction ensures long-term trust and repeat business.

Website: www.transworldequipment.com

Company Overview: Cryo-Tech is dedicated to advancing society through cryogenic solutions founded on integrity, fairness, and customer focus. The company offers comprehensive services across the entire business cycle—from development and procurement to production, logistics, and sales—ensuring tailored solutions for each client’s unique needs. Leveraging strong financial resources, advanced technology, and a highly skilled team, Cryo-Tech anticipates market trends to develop innovative products and systems that address emerging demands. Its expertise covers a wide range of cryogenic applications, providing customers with complete, integrated solutions for storage, transportation, and processing. Over the years, Cryo-Tech has built a reputation for reliability, technical excellence, and customer trust. With a forward-thinking approach and unwavering dedication, the company remains committed to delivering world-class cryogenic solutions that drive progress and sustainability.

Offerings:

Why Choose Cryo-Tech

Cryo-Tech provides complete cryogenic solutions with a strong focus on innovation, quality, and customer relationships. Its ability to deliver integrated services—from development to logistics—makes it a reliable partner for businesses seeking end-to-end support in cryogenic applications.

Why Cryo-Tech Standed Out

Cryo-Tech’s strength lies in its proactive approach to market trends, advanced technological capabilities, and a dedicated team committed to excellence. Its combination of financial stability, technical expertise, and innovative spirit allows it to create tailored, future-ready cryogenic systems that exceed industry expectations.

Website: www.cryogenictank.com

| Manufacturer | Tank Type(s) | Typical Capacity / Range | Insulation / Thermal Technology | Design Pressure / Key Features |

|---|---|---|---|---|

| Linde Engineering | Vertical & horizontal vacuum-insulated cryogenic tanks; packaged bulk tanks | Small → large shop-fabricated tanks (typical product lines from ~3,000 L up to large engineered vessels) | Vacuum + perlite with molecular-sieve (vacuum-perlite) multi-layer insulation | Working pressures commonly 18 / 22 / 36 bar classes for various models; widely used in plant & terminal applications |

| McDermott (CB&I) | Full-containment prestressed concrete tanks and double-walled steel tanks for large LNG terminals | Very large terminal tanks, typically 165,000–200,000 m³ class | Concrete outer containment + steel inner tank (full-containment design) | Engineered for large-scale LNG import/export projects with highest safety standards |

| Wärtsilä | IMO Type-C pressure tanks for marine and bunkering applications | Small to mid-scale marine LNG tanks from tens to several thousand m³ | Double-wall vacuum insulated or polyurethane foam insulated systems | Typical design pressures around 4–9 bar for marine fuel systems |

| IHI Corporation | Pre-stressed concrete full-containment tanks and large double-walled metal tanks | Large terminal tanks in the 10⁴–10⁵ m³ class | Concrete outer structure with 9% Ni steel inner liner | Global leader in large LNG receiving terminal tank construction |

| CIMC ENRIC | Double-wall vacuum insulated tanks and turnkey storage systems | Approximately 200 m³ to 50,000 m³ depending on configuration | Perlite or high-vacuum multi-layer insulation | Provides shop-fabricated and field-erected tanks with turnkey solutions |

| Chart Industries | Vertical/horizontal bulk cryogenic tanks, micro-bulk systems | From ~6,000 L micro-bulk to ~1,000,000 L bulk tanks | Vacuum insulated perlite or Chart Composite Super Insulation™ | Pre-engineered tanks with various MAWP ratings up to 12–37 bar |

| INOXCVA (INOX Group) | Vacuum insulated bulk tanks and ISO transport tanks | From ~4,000 L up to 1,000,000 L bulk storage | Vacuum perlite or multi-layer super-insulation | Turnkey storage and vaporization systems compliant with ASME/EN standards |

| Cryeng Group | Vacuum-insulated LNG and cryogenic storage tanks; fueling station systems | Small to medium industrial tanks from approximately 3,000 L up to 200,000+ L depending on project requirements | High-vacuum perlite or multi-layer insulation for long hold times and low boil-off rates | Designed to ASME and EN standards; custom-engineered solutions for LNG fueling, industrial gas storage, and energy projects |

| TransWorld Equipment | ISO LNG tank containers and intermodal transport modules | Typical 40’ ISO LNG tank around 36,700 L gross capacity | Vacuum insulated double-wall ISO transport tanks | Specialist in intermodal LNG transport solutions |

| Special Recommended — Cryo-Tech | Static and transport cryogenic tanks and turnkey systems | From small station tanks to larger customized static tanks | Vacuum + perlite or multi-layer insulation | Recommended supplier for diversified cryogenic applications |

The global LNG industry relies on the expertise of top-tier LNG tank manufacturers to meet the rising demand for clean energy solutions. Companies like Linde, McDermott, Wärtsilä, and Cryo-Tech lead the way with innovative, reliable, and efficient LNG storage and transportation tanks. Whether for large-scale terminals, marine applications, or vehicle fueling, these manufacturers provide critical infrastructure to support the energy transition. By choosing a trusted LNG tank manufacturer, businesses can ensure safety, sustainability, and performance in their LNG operations.

1. What is an LNG storage tank?

An LNG storage tank is a specially designed cryogenic vessel used to store liquefied natural gas at extremely low temperatures of around –162°C. These tanks are built with advanced insulation systems to minimize heat transfer and reduce boil-off gas, ensuring safe and efficient long-term LNG storage for terminals, industrial facilities, and fueling stations.

2. What are the main types of LNG tanks?

LNG tanks generally fall into three categories: vacuum-insulated double-wall tanks, full-containment tanks, and membrane tanks. Vacuum-insulated tanks are commonly used for small and medium capacities, while full-containment concrete tanks are typically applied in large LNG terminals. Membrane tanks are mainly used for marine and specialized large-scale applications.

3. How do I choose the right LNG tank manufacturer?

Choosing the right manufacturer depends on several factors, including project capacity, application scenario, required certifications (such as ASME, EN, or ISO standards), delivery time, budget, and after-sales support. It is important to evaluate the supplier’s technical experience, past project references, and ability to provide customized engineering solutions.

4. What insulation technologies are used in LNG tanks?

The most common insulation methods include vacuum-perlite insulation, multi-layer vacuum insulation, polyurethane foam insulation, and full-containment concrete structures with insulated liners. The choice of insulation technology depends on tank size, operating conditions, and required holding time.

5. What is the typical capacity range of LNG storage tanks?

LNG tanks can range from small 3,000-liter microbulk tanks to large terminal storage tanks exceeding 200,000 cubic meters. Small and medium tanks are usually used for industrial gas supply and LNG fueling stations, while very large tanks are designed for LNG import/export terminals.

![Top 10 LNG Tank Manufacturers Worldwide[2026 Updated]](/statics/images/right.png)

![Top 10 LNG Tank Manufacturers Worldwide[2026 Updated]](/uploads/202506/CryoTech-banner-1-_1750490922_WNo_800d450.jpg)

![Top 10 Cryogenic Companies in USA[2026 Updated]](/statics/images/right.png)

![Top 10 Cryogenic Companies in USA[2026 Updated]](/uploads/202508/bannerlist_1756363009_WNo_800d450.jpg)