1. Introduction: Why Material Selection is Critical for Cryogenic Tanks

Cryogenic tanks are specialized storage systems designed to hold liquefied gases such as LNG, LPG, liquid nitrogen, oxygen, argon, and CO₂ at extremely low temperatures. The choice of material directly impacts thermal insulation performance, safety under extreme pressure, and long-term operational reliability. This article explores the materials used in cryogenic tank construction, the engineering principles behind them, and how CryoTech ensures compliance with global standards.

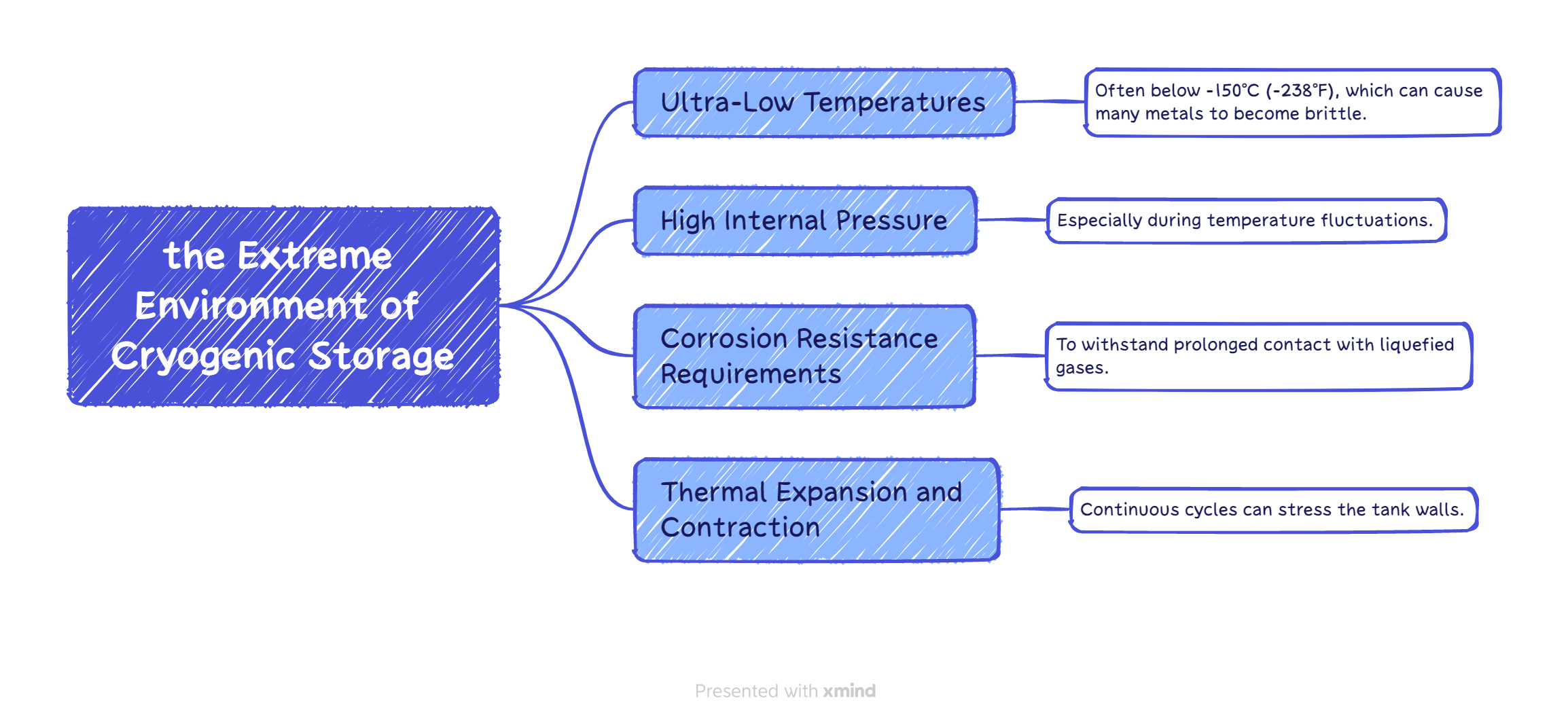

2. Understanding the Extreme Environment of Cryogenic Storage

- Ultra-Low Temperatures: Often below -150°C (-238°F), which can cause many metals to become brittle.

- High Internal Pressure: Especially during temperature fluctuations.

- Corrosion Resistance Requirements: To withstand prolonged contact with liquefied gases.

- Thermal Expansion and Contraction: Continuous cycles can stress the tank walls.

The right material choice mitigates these risks while ensuring the tank’s longevity and safety.

3. Core Materials Used in Cryogenic Tank Construction

| Component | Common Material Choices | Key Properties |

|---|---|---|

| Inner Vessel | Austenitic stainless steel (304, 304L, 316L) | High toughness at low temperatures, corrosion resistance |

| Outer Shell | Carbon steel or stainless steel | Structural integrity, weather protection |

| Insulation Layer | Perlite powder, multi-layer vacuum insulation | Minimizes heat transfer, maintains low boil-off rate |

| Piping & Valves | Stainless steel, brass (for certain gases) | Leak prevention, compatibility with cryogens |

4. Why Austenitic Stainless Steel is the Industry Standard

Austenitic stainless steels, particularly 304L and 316L grades, are widely used for the inner vessel because they retain ductility and toughness at -196°C, offer excellent corrosion resistance against oxygen, nitrogen, and LNG, and have low carbon content to improve weldability. CryoTech uses low-temperature impact-tested stainless steel to ensure tanks meet ISO, ASME, and EN standards.

5. The Role of Carbon Steel in Outer Shells

While stainless steel is ideal for the inner tank, carbon steel is often used for the outer shell because it provides high structural strength at a lower cost. Since the outer shell does not directly contact cryogenic liquids, brittleness is less of a concern, and protective coatings prevent environmental damage.

6. Advanced Insulation Technologies

- Vacuum-Perlite Insulation: Fine perlite powder and high vacuum reduce heat transfer.

- Multi-Layer Insulation (MLI): Alternating reflective foil and spacers improve efficiency.

This combination minimizes boil-off losses and improves energy efficiency for LNG transport and storage.

7. Welding & Fabrication Considerations

Material selection is only effective with precise fabrication techniques:

- Low-temperature welding consumables to prevent embrittlement.

- Post-weld heat treatment for stress relief.

- Non-destructive testing (NDT) to ensure weld integrity.

CryoTech uses automated welding systems and strict quality control to guarantee each tank's performance.

8. Industry Applications & Custom Material Solutions

Cryogenic tanks are used in:

- Energy: LNG/LPG storage for offshore and onshore facilities.

- Medical: Liquid oxygen, nitrogen, argon.

- Industrial Manufacturing: Steelmaking, electronics, chemical plants.

- Space & Aerospace: Liquid hydrogen and oxygen for rockets.

CryoTech offers custom-engineered material combinations to match client needs, balancing cost, performance, and compliance.

9. Compliance with International Standards

All materials must comply with:

- ASME Section VIII – Pressure vessel standards

- EN 13458 / EN 13530 – Cryogenic vessel requirements

- ISO 21009 – Design, fabrication, and inspection guidelines

CryoTech ensures all tanks are certified with full material test reports (MTRs).

10. Conclusion: Material Science Meets Engineering Excellence

The strength of a cryogenic tank lies in the synergy between material science, precise engineering, and rigorous testing. From austenitic stainless steel interiors to carbon steel exteriors and vacuum-perlite insulation, every choice plays a role in safety, efficiency, and lifespan. With decades of expertise and a focus on customized solutions, CryoTech continues to lead in delivering reliable, certified, and high-performance cryogenic tanks worldwide.

.png)

.png)