What is a Cryogenic Tank? A Comprehensive Guide

A cryogenic tank is a specialized container designed to store and transport materials at extremely low temperatures, typically below -150°C (-238°F). These tanks are crucial for maintaining the liquid state of cryogenic fluids, like liquid nitrogen, oxygen, argon, and helium, which are used in various industrial, medical, and research applications. Understanding what a cryogenic tank involves exploring its design, features, applications, and the types of these tanks cryogenic liquids it stores. This comprehensive guide provides insights into the functionality and significance of cryogenic tanks, with a focus on their role in modern industries.

Table of Contents

-

Introduction to Cryogenic Tanks

-

Key Features of Cryogenic Tanks

-

Types of Cryogenic Liquids

-

Applications of Cryogenic Tanks

-

Design and Construction of Cryogenic Tanks

-

Safety Considerations for Cryogenic Tanks

-

Maintenance and Inspection of Cryogenic Tanks

-

Conclusion

Introduction to Cryogenic Tanks

Cryogenic tanks are engineered to handle extreme cold, making them essential for industries that rely on liquefied gases. These tanks ensure that materials like liquid nitrogen or helium remain in their liquid form, which is critical for applications ranging from medical preservation to industrial manufacturing. The question, what is a cryogenic tank, encompasses not just its function but also its sophisticated design and diverse uses. By maintaining temperatures far below ambient conditions, cryogenic tanks enable the safe storage and transportation of highly volatile substances.

Key Features of Cryogenic Tanks

The following information is sourced from Google’s AI summary and presented without modification:

-

Low Temperature Storage: Cryogenic tanks are engineered to keep materials in a liquid state at very low temperatures, often by using a vacuum jacket and insulating materials to minimize heat transfer.

-

Thermal Insulation: A key component of these tanks is the insulation, which can include multilayer insulation and a vacuum to reduce heat ingress and prevent evaporation of the stored liquid.

-

Double-Walled Construction: Many cryogenic tanks have a double-walled design with a vacuum between the inner and outer vessels to further enhance insulation.

-

Pressure Vessels: Some cryogenic tanks are also pressure vessels, designed to withstand the pressure generated by the cryogenic liquid.

-

Diverse Applications: They are used to store and transport liquefied gases for various industries, including metal processing, medical technology, electronics, food processing, and energy generation.

These features highlight why cryogenic tanks are indispensable for handling cryogenic fluids safely and efficiently.

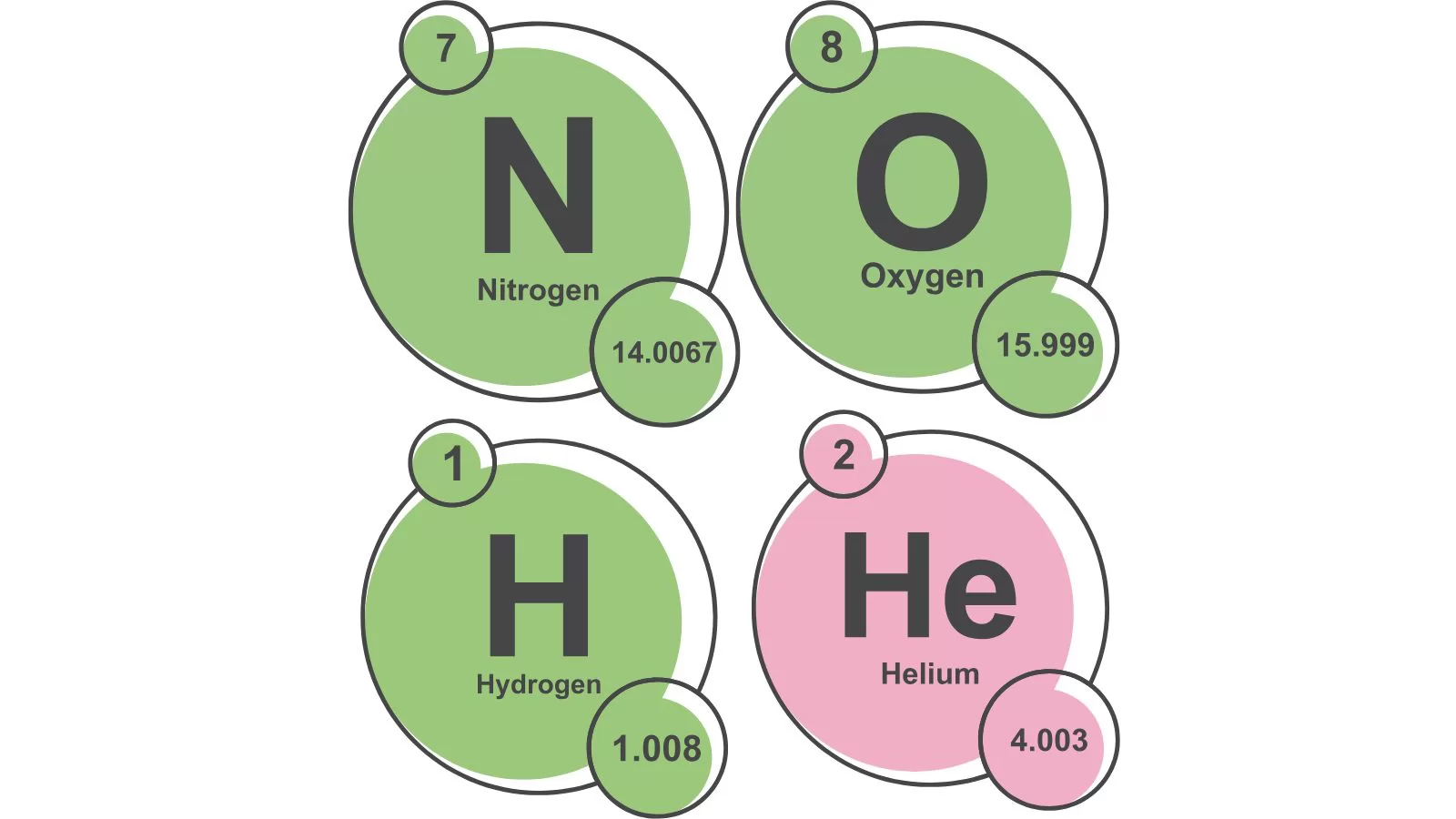

Types of Cryogenic Liquids

Below is the Google AI summary content regarding cryogenic liquids, included verbatim:

-

Liquid Nitrogen: Used for freezing and preserving samples, as well as in some industrial processes.

-

Liquid Oxygen: Essential for medical and industrial applications, such as in hospitals and steel production.

-

Liquid Hydrogen: Used in some fuel cell technologies and research.

-

Liquid Helium: Used for cooling superconducting magnets and in various low-temperature research applications.

Each of these liquids has unique properties, requiring specialized cryogenic tanks tailored to their specific temperature and pressure requirements.

Applications of Cryogenic Tanks

Cryogenic tanks serve a wide array of industries due to their ability to store and transport liquefied gases safely. Some key applications include:

-

Medical Industry: Liquid oxygen is vital for respiratory therapy in hospitals, while liquid nitrogen is used for cryopreservation of biological samples, such as cells and tissues.

-

Industrial Manufacturing: Liquid oxygen supports combustion processes in steel production, and liquid nitrogen is used in metal processing to achieve precise cooling.

-

Electronics: Cryogenic fluids like helium are used in the production of semiconductors, where ultra-low temperatures are necessary.

-

Food Processing: Liquid nitrogen enables rapid freezing, preserving food quality and extending shelf life.

-

Energy Sector: Liquid hydrogen is explored as a clean fuel source in fuel cell technology, and liquid natural gas (LNG) is stored in cryogenic tanks for energy distribution.

-

Scientific Research: Liquid helium cools superconducting magnets in MRI machines and particle accelerators, enabling cutting-edge discoveries.

By addressing the question what is a cryogenic tank, it becomes clear that these tanks are pivotal in advancing technology and improving quality of life across sectors.

Design and Construction of Cryogenic Tanks

The design of a cryogenic tank is a feat of engineering, balancing thermal efficiency, structural integrity, and safety. Most tanks feature:

-

Inner Vessel: Made of stainless steel or other materials resistant to low temperatures, this holds the cryogenic liquid.

-

Outer Vessel: Typically made of carbon steel, it encases the inner vessel and supports the vacuum insulation.

-

Vacuum Insulation: The space between the inner and outer vessels is evacuated to create a vacuum, minimizing heat transfer via conduction and convection.

-

Multilayer Insulation (MLI): Reflective layers reduce radiative heat transfer, further enhancing insulation.

-

Support Systems: Structural supports maintain the inner vessel’s position while allowing for thermal contraction at low temperatures.

-

Safety Valves and Gauges: These monitor and regulate pressure to prevent over-pressurization.

The construction process adheres to strict standards, such as those set by the American Society of Mechanical Engineers (ASME) or European Pressure Equipment Directive (PED), ensuring reliability and safety.

Safety Considerations for Cryogenic Tanks

Handling cryogenic liquids poses unique risks, necessitating robust safety measures:

-

Extreme Cold Hazards: Contact with cryogenic liquids can cause severe frostbite or cryogenic burns, requiring protective equipment like insulated gloves and face shields.

-

Pressure Build-Up: As cryogenic liquids warm, they expand rapidly, potentially causing tank rupture if pressure relief systems fail.

-

Oxygen Enrichment: Leaks of liquid oxygen can create oxygen-rich environments, increasing fire risks.

-

Asphyxiation Risks: In confined spaces, evaporating cryogenic liquids like nitrogen can displace oxygen, posing suffocation hazards.

Operators must follow rigorous protocols, including regular training, proper ventilation, and adherence to safety standards, to mitigate these risks.

Maintenance and Inspection of Cryogenic Tanks

To ensure longevity and safety, cryogenic tanks require regular maintenance and inspection:

-

Visual Inspections: Check for signs of corrosion, leaks, or damage to the outer vessel.

-

Vacuum Testing: Verify the integrity of the vacuum insulation to ensure thermal efficiency.

-

Pressure Relief Valve Checks: Test valves to confirm they function correctly under pressure.

-

Insulation Monitoring: Assess multilayer insulation for degradation over time.

-

Compliance Audits: Ensure tanks meet regulatory standards through periodic certifications.

Proactive maintenance minimizes downtime and extends the service life of cryogenic tanks, ensuring they perform reliably in demanding applications.

Conclusion

In summary, a cryogenic tank is a highly specialized vessel designed to store and transport cryogenic liquids at ultra-low temperatures, enabling critical applications across industries like healthcare, manufacturing, and research. By addressing what is a cryogenic tank, this guide has explored its key features, types of liquids stored, applications, design, safety considerations, and maintenance needs. For businesses seeking reliable cryogenic solutions, Cryo-Tech offers cutting-edge cryogenic tanks designed to meet diverse industry demands. Visit their website at https://www.cryogenictank.com/ to explore their innovative products and services.