A cryogenic pump, or cryopump, is a specialized vacuum pump that uses ultra-low temperatures to create high-vacuum environments by capturing gases and vapors. Essential in industries like semiconductor manufacturing, aerospace, and medical technology, these pumps are critical for processes requiring clean, particle-free conditions. At CryogenicTank.com, we leverage our expertise in cryogenic systems to help industries optimize their operations. In this guide, we’ll explore what a cryogenic pump is, how it works, its types, applications, and why it’s a game-changer for modern technology.

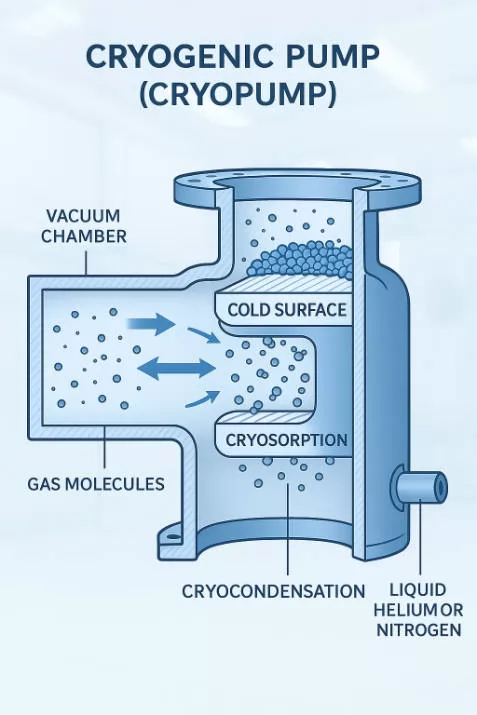

A cryogenic pump, commonly known as a cryopump, is a high-vacuum pump that traps gases and vapors by condensing them on a cold surface, typically cooled to temperatures below -150°C using liquid helium or nitrogen. Unlike traditional vacuum pumps, cryopumps have no moving parts, making them highly reliable for ultra-high vacuum (UHV) environments. They are widely used in applications requiring extreme cleanliness, such as semiconductor fabrication and space simulation.

At CryogenicTank.com, our cryogenic solutions complement these pumps, ensuring efficient storage and handling of cryogenic fluids.

Cryogenic pumps operate by cooling a surface to cryogenic temperatures, causing gas molecules to condense or adsorb onto it, effectively removing them from the environment to create a vacuum. Think of it as a sponge that freezes gas molecules in place. The process involves cryocondensation (turning gases into solids) and cryosorption (trapping gases on a porous surface). For example, in semiconductor manufacturing, cryopumps maintain ultra-clean conditions for producing microchips.

Cryogenic pumps come in various types, each suited for specific applications. Below are the most common types:

| Type | Cooling Method | Applications |

|---|---|---|

| Closed-Cycle | Refrigerator | Semiconductor manufacturing |

| Bath Cryopump | Liquid cryogens | Space simulation |

| Hybrid | Combined | Particle accelerators |

Cryogenic pumps are vital in industries requiring ultra-high vacuum conditions. Key applications include:

At CryogenicTank.com, our cryogenic storage solutions integrate seamlessly with cryopumps to support these industries.

Benefits:

Limitations:

Cryogenic pumps differ from other vacuum pumps like turbomolecular or diffusion pumps. Here’s a comparison:

| Feature | Cryogenic Pump | Turbomolecular Pump | Diffusion Pump |

|---|---|---|---|

| Mechanism | Cryocondensation | Mechanical blades | Oil vapor jet |

| Vacuum Level | Ultra-high | High | High |

| Applications | Semiconductors | Research | Industrial |

Cryogenic pumps are ideal for industries requiring precision and reliability. Whether you’re in aerospace, medical, or research, these pumps deliver unmatched vacuum performance. At CryogenicTank.com, we provide tailored cryogenic solutions to complement cryopump technology, ensuring your operations run smoothly.

Cryogenic pumps are indispensable for creating high-vacuum environments in cutting-edge industries. From their unique cooling mechanisms to their wide-ranging applications, they offer unmatched performance for specialized needs. Have questions about cryogenic pumps or need help choosing the right system? Contact CryogenicTank.com or share your thoughts in the comments below!

A cryopump uses cryogenic temperatures to trap gases, while a turbopump relies on high-speed blades. Cryopumps are ideal for ultra-clean environments.

Cryopumps require regeneration every few months, depending on usage, to remove trapped gases.

![Top 10 LNG Tank Manufacturers Worldwide[2026 Updated]](/statics/images/right.png)

![Top 10 LNG Tank Manufacturers Worldwide[2026 Updated]](/uploads/202506/CryoTech-banner-1-_1750490922_WNo_800d450.jpg)

![Top 10 Cryogenic Companies in USA[2026 Updated]](/statics/images/right.png)

![Top 10 Cryogenic Companies in USA[2026 Updated]](/uploads/202508/bannerlist_1756363009_WNo_800d450.jpg)